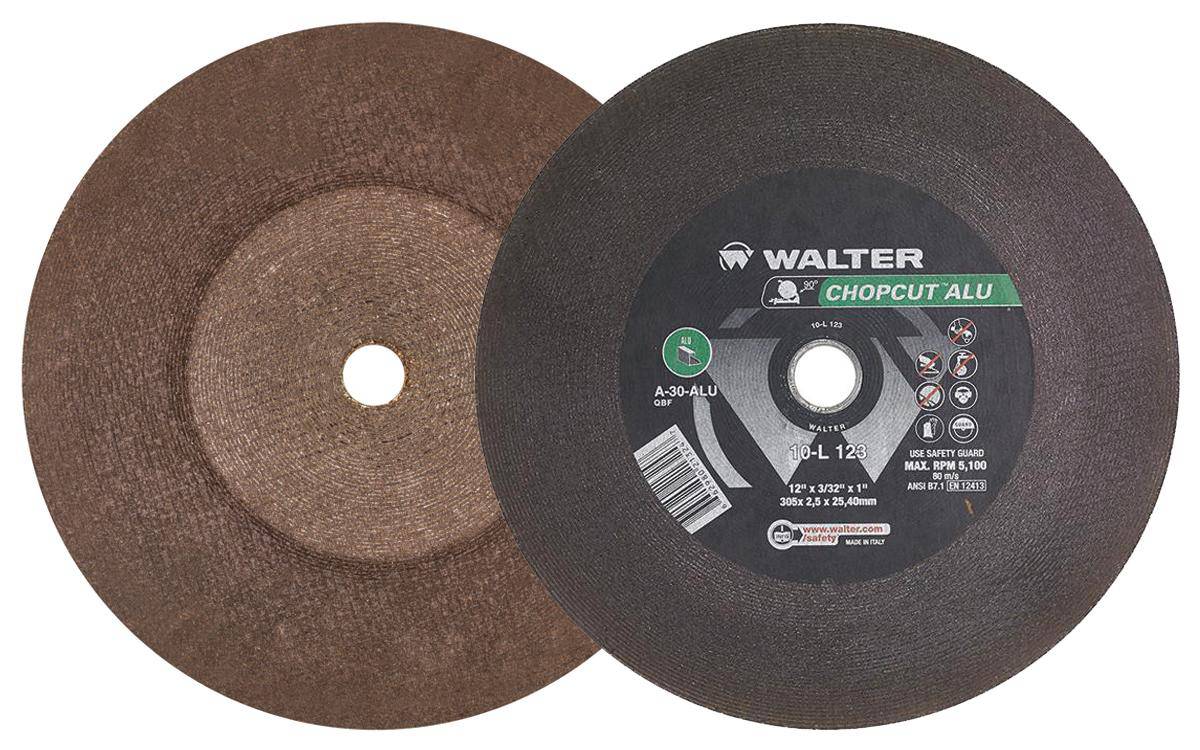

The Walter 10L123 Chopcut Aluminum wheel represents a significant advancement in abrasive technology for non-ferrous metal fabrication. Cutting soft metals like aluminum, copper, and brass with standard abrasive wheels often leads to a phenomenon known as "loading" or "clogging." This occurs when the soft metal melts and adheres to the abrasive grains, effectively smoothing out the cutting surface and rendering the wheel useless. The Walter Chopcut Alu is engineered with a unique formulation that actively prevents this adhesion, ensuring that fresh abrasive grains are constantly exposed to the workpiece.

Designed specifically for use with portable chop saws, this 12-inch wheel features a 3/32-inch thickness and a 1-inch arbor, making it compatible with most standard machines in this category. The wheel's composition is balanced to provide a rapid cut rate while minimizing the load on the saw's motor. This is crucial for portable tools, which can easily overheat or bog down when faced with the high friction of cutting aluminum. By maintaining a free-cutting action, the Chopcut wheel extends the life of both the consumable and the power tool itself.

In industrial environments where efficiency is paramount, the 10L123 reduces downtime associated with wheel changes and dressing. Operators can move seamlessly between cutting tasks involving different non-ferrous profiles, such as tubing, extrusion, and bar stock. The structural integrity of the wheel is reinforced to handle the stresses of chopping applications, providing a safe and reliable cutting solution for professional fabricators and maintenance personnel.

Whether you are working in a dedicated aluminum fabrication shop or a general maintenance department, the Walter Chopcut Alu wheel offers a specialized solution that outperforms general-purpose abrasives. Its ability to deliver clean, burr-minimized cuts without the frustration of glazing makes it an essential inventory item for any operation dealing with non-ferrous metals.

| Additional Information |

|---|

| Packaging Description:10 per each |

| Diameter (in):12" |

| Thickness (in):3/32" |

| Arbor (in):1" |

| Used to Cut:Aluminum |

| Application:Aluminum, Non-Ferrous Metals |

| ----- new values below ---- |

| Application:Aluminum, Non-Ferrous Metals |

| Tool Compatibility:Portable Chop Saw |

| Wheel Type:Type 1 |

| brand:Walter |

| diameter-in:12" |

| thickness-in:3/32" |

| arbor-in:1" |

| used-to-cut:Aluminum |