The Walter 10A206 Ripcut Cut-Off Wheel represents the pinnacle of abrasive technology for heavy-duty industrial applications. Specifically engineered for stationary cut-off machines possessing a power output exceeding 10HP, this 20-inch wheel is formulated to endure the rigorous demands of continuous production environments. In settings where downtime equates to lost revenue, the Ripcut's 'Long Life' composition significantly extends the intervals between wheel changes, thereby optimizing operational efficiency and reducing total abrasive costs.

Industrial fabrication often involves a diverse range of structural profiles. The Ripcut 10A206 is versatile enough to handle this variety without compromising performance. Whether processing thin-walled structural shapes or severing dense, solid steel shafts, the wheel maintains structural integrity and cutting speed. This adaptability reduces the need for inventorying multiple wheel types for different steel applications, streamlining procurement and stock management.

Safety and stability are paramount when operating large-diameter abrasives at high speeds. Walter Surface Technologies has designed the Ripcut series to provide a stable, vibration-resistant cutting experience. The wheel's matrix is reinforced to handle the torque generated by high-horsepower motors, ensuring straight, accurate cuts that minimize secondary machining or deburring requirements. By choosing the 10A206, facility managers invest in a consumable that balances aggressive material removal with exceptional durability.

Ultimately, the Walter Ripcut 20-inch wheel is a strategic choice for fabrication shops and steel service centers. Its formulation is tuned to deliver the most cost-effective cuts in the market, leveraging the power of heavy machinery to drive productivity. When paired with appropriate equipment, it outperforms standard alternatives, delivering consistent results cut after cut.

| Additional Information |

|---|

| Packaging Description:5 per each |

| Diameter (in):20" |

| Used to Cut:Steel |

| Item:Cut-Off Wheel |

| Application Type:Heavy Duty |

| ----- new values below ---- |

| Machine Requirement:Stationary machines > 10HP |

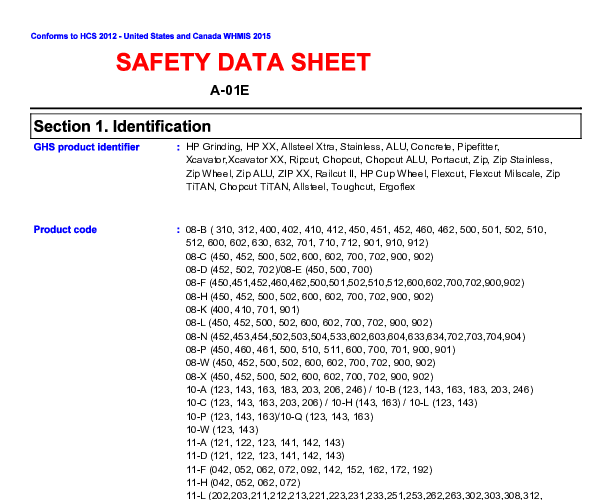

| Product Line:Ripcut |

| Application Type:Heavy Duty |

| Brand:Walter |

| Diameter (in):20" |

| Used to Cut:Steel |

| Item:Cut-Off Wheel |