The Walter 15F524 Mounted Flap Wheel represents the pinnacle of abrasive engineering for precision finishing applications. Designed for industrial environments where surface consistency and tool longevity are paramount, this 2-1/2" x 1-1/2" wheel utilizes a premium 240-grit abrasive cloth. The manufacturing process ensures a perfectly balanced tool, with flaps securely bonded to a central hub. This construction minimizes vibration, thereby protecting the workpiece from chatter marks and reducing mechanical stress on the power tool's bearings. The 240-grit composition is specifically selected for fine finishing tasks, capable of producing a uniform satin finish that meets strict roughness average (Ra) requirements.

One of the critical challenges in metal finishing is maintaining a consistent cut rate as the abrasive wears. Walter's flap wheel design addresses this by ensuring that as the outer flaps wear down, fresh, sharp abrasive grain is continuously exposed. This self-sharpening characteristic guarantees that the finish quality remains uniform from the first pass until the wheel is worn to the hub. The flexibility of the flaps allows the wheel to conform to irregular shapes and contours, making it an indispensable tool for finishing inner diameters of pipes, complex machined parts, and tight corners where rigid grinding wheels cannot reach.

Metallurgical integrity is preserved through the cool-cutting action of the flap configuration. By allowing airflow between the flaps, heat generation is significantly reduced compared to solid bonded abrasives. This feature is particularly critical when working with heat-sensitive materials like stainless steel and aluminum, preventing heat discoloration and warping. The 15F524 is engineered to be compatible with a wide range of die grinders and rotary tools, providing a versatile solution for MRO professionals and fabrication specialists seeking to elevate their finishing standards.

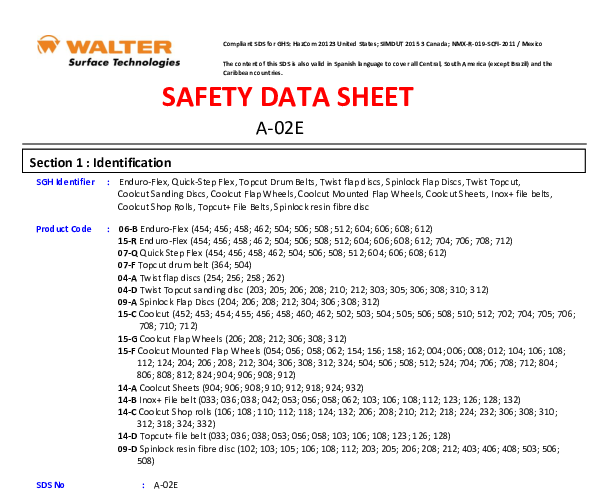

| Additional Information |

|---|

| Packaging Description:1 per each |

| Grit:240 |

| Width (in):1.5" |

| Used to Sand:Steel or Stainless or Aluminum |

| Diameter:2-1/2" |

| Width:1-1/2" |

| Mounting Type:Shaft Mounted |

| Abrasive Material:Industrial-grade abrasive cloth |

| ----- new values below ---- |

| Diameter:2-1/2" |

| Grit:240 |

| Width:1-1/2" |

| Mounting Type:Shaft Mounted |

| Abrasive Material:Industrial Grade Abrasive Cloth |

| Brand:Walter |

| Grit:240 |

| Width (in):1.5" |

| Used to Sand:Steel or Stainless or Aluminum |

| Packaging Description:1 per each |