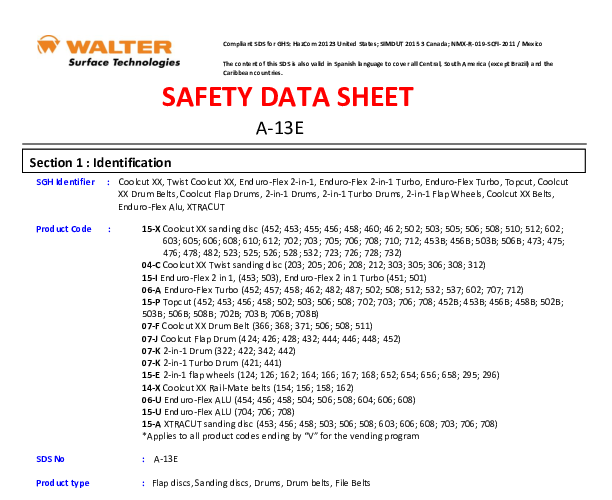

The Walter 15E126 Two-in-One Flap Wheel is an innovative abrasive solution designed to enhance productivity in industrial maintenance, repair, and operations (MRO). In many fabrication and finishing environments, operators are forced to switch between aggressive grinding tools and softer finishing pads to achieve the desired surface quality. This product eliminates that bottleneck by combining two distinct materials into a single wheel: aggressive coated abrasive cloth and non-woven Blendex material. This hybrid design allows the wheel to remove surface imperfections, such as light scratches or oxidation, while simultaneously laying down a smooth, consistent satin finish.

Measuring 2 inches in diameter and 1 inch in width, this mounted wheel is perfectly sized for tight spaces, internal diameters of pipes, and intricate metal parts. The 1/4-inch shaft ensures compatibility with standard pneumatic or electric die grinders, making it a versatile addition to any tool crib. For facility managers and procurement specialists, adopting the Two-in-One series can lead to reduced inventory requirements, as one SKU can often replace two separate consumable products (a sanding disc and a finishing pad).

The "Extra Fine" grit rating of the 15E126 is specifically engineered for final finishing stages where aesthetic quality is paramount. It is particularly effective on stainless steel, aluminum, and other non-ferrous metals where heat buildup can cause warping or discoloration. The cool-running nature of the Blendex material helps dissipate heat, protecting the workpiece and ensuring a uniform appearance batch after batch. Whether used for cleaning up machinery components, prepping surfaces for coating, or general metal maintenance, this Walter flap wheel delivers consistent, professional results.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Diameter (in):2" |

| Width (in):1" |

| Grit:Extra Fine |

| Used to Grind:Stainless, Steel, Aluminum |

| Used to Sand:Aluminum, Stainless |

| Product Type:Mounted Flap Wheel |

| Series:Two-In-One |

| Max RPM:20000 |

| ----- new values below ---- |

| Shaft Size:1/4" |

| Product Type:Mounted Flap Wheel |

| Series:Two-in-One |

| Max RPM:20000 |

| Brand:Walter |

| Diameter (in):2 |

| Width (in):1 |

| Grit:Extra Fine |

| Used to Grind:Stainless, Steel, Aluminum |

| Used to Sand:Stainless, Aluminum |