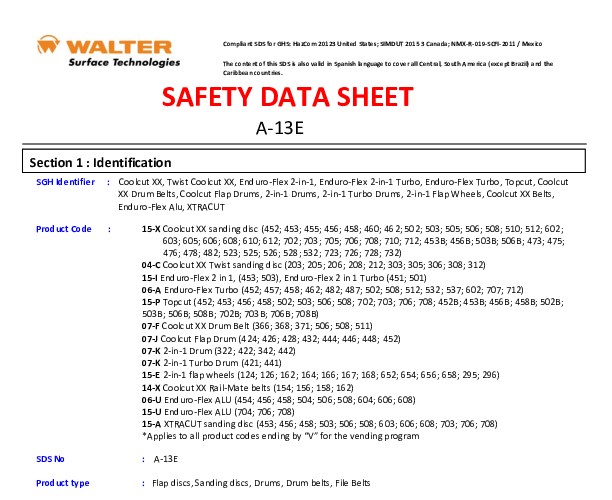

The Walter Two-In-One™ flap wheel (SKU: 15E658) represents a significant leap in abrasive efficiency for industrial metal finishing. Engineered with a unique interleaved construction, this 3-inch by 1-1/2-inch wheel alternates flaps of high-quality coated abrasive cloth with layers of non-woven conditioning material. This hybrid design allows the wheel to perform two distinct operations simultaneously: the coated abrasive flaps aggressively remove surface imperfections, light scratches, and handling marks, while the non-woven flaps cushion the cut and generate a smooth, uniform satin finish. This dual-action capability effectively consolidates the traditional multi-step process of grinding followed by blending into a single, streamlined operation.

Designed for precision and consistency, the Two-In-One wheel is particularly effective on heat-sensitive materials such as stainless steel, aluminum, brass, and copper. The non-woven material promotes airflow and reduces friction, ensuring a cool cutting action that minimizes the risk of heat discoloration or warping on thin-walled components. The threaded mounting system ensures a secure, vibration-free connection to compatible power tools, enhancing operator control and safety during intricate finishing tasks. For MRO professionals and fabrication shops looking to optimize workflow and reduce consumable inventory, this wheel offers a high-performance solution for achieving pharmaceutical or food-grade finishes on stainless steel equipment.

In industrial applications, the 15E658 is optimized for final blending, graining, and edge polishing. Its compact 3-inch diameter allows for access into tighter spaces and contours that larger drums cannot reach. The wheel's ability to maintain a consistent finish throughout its lifespan reduces rework and ensures part-to-part uniformity in production environments. By eliminating the need to switch between a dedicated grinding wheel and a separate finishing pad, operators can significantly reduce downtime and labor costs associated with tool changes.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Diameter (in):3 |

| Width (in):1.5" |

| Used to Sand:Stainless or Aluminum |

| Product Type:Two-In-One Flap Wheel |

| Construction:Interleaved Coated Abrasive & Non-Woven |

| Mounting Type:Threaded |

| Application Material:Aluminum, Brass, Copper, Stainless Steel |

| ----- new values below ---- |

| Product Type:Two-In-One Flap Wheel |

| Construction:Interleaved Coated Abrasive & Non-Woven |

| Mounting Type:Threaded |

| Application Material:Aluminum, Brass, Copper, Stainless Steel |

| Brand:Walter |

| Diameter (in):3" |

| Width (in):1.5" |

| Used to Sand:Stainless or Aluminum |