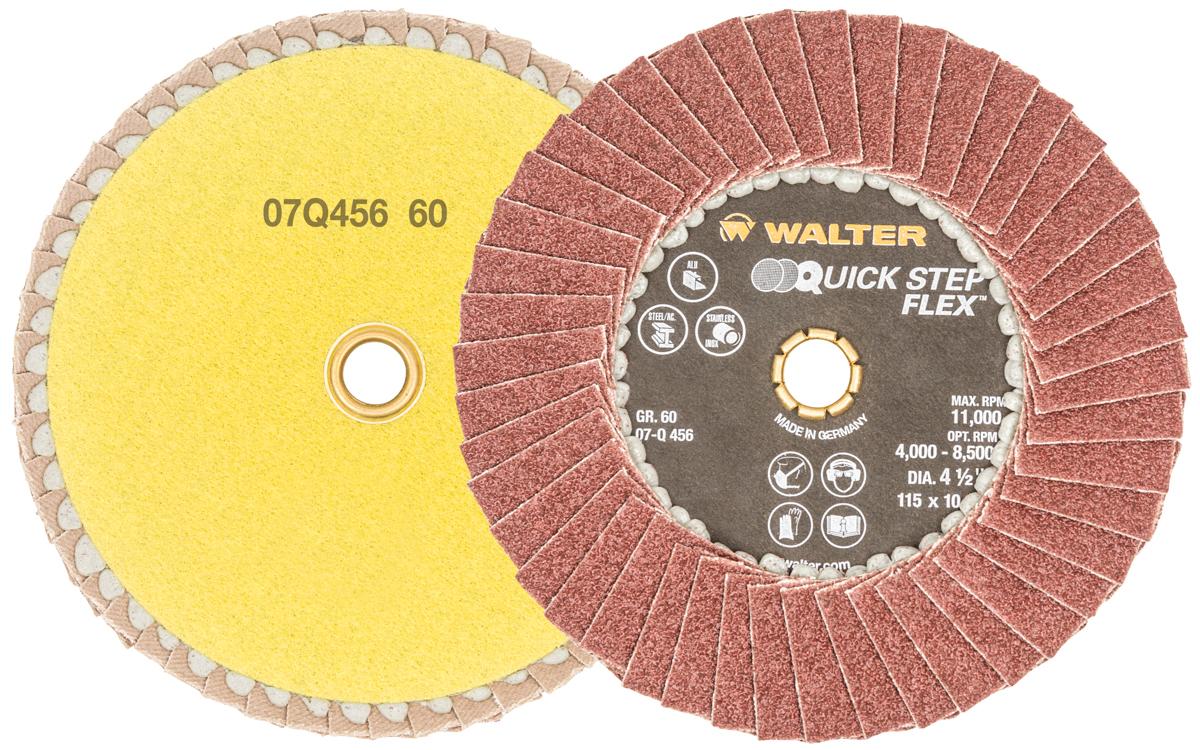

The Walter 07Q456 Quick-Step Flex Blender Disc is a specialized abrasive tool designed to bridge the gap between aggressive grinding and fine surface finishing. Engineered with a 4-1/2 inch diameter and a coarse 60 grit abrasive, this disc is optimized for the removal of light welds, deburring operations, and edge breaking on ferrous metals. The defining characteristic of the Flex series is its pliable backing material, which allows the abrasive flaps to conform to the workpiece geometry. This feature is critical when processing curved surfaces, pipes, or rounded corners where rigid discs typically cause flat spots or gouging.

Manufactured in Germany, the disc employs a high-quality abrasive matrix that delivers cool cutting performance, significantly reducing the risk of heat discoloration on the substrate. The construction ensures a vibration-free experience, enhancing operator control and reducing fatigue during extended use. It is compatible with Walter's Quick-Step mounting system, facilitating rapid changeovers and minimizing downtime in high-throughput industrial environments. This product is specifically rated for use on mild steel, cast iron, tool steel, and high-tensile steel alloys.

By combining material removal and blending into a single operation, the Quick-Step Flex reduces the number of processing steps required to achieve a paint-ready or uniform finish. This efficiency makes it a cost-effective solution for MRO workshops and fabrication facilities dealing with complex metal shapes. The package contains 10 discs, ensuring a ready supply for continuous production workflows.

| Additional Information |

|---|

| Packaging Description:10 per each, 10 per each (10-per-each) |

| Diameter (in):4.5" (4-5) |

| Grit:60 (60) |

| Used to Grind:Steel (steel) |

| Backing Material:Flexible |

| ----- new values below ---- |

| Backing Material:Flexible |

| Mounting System:Quick-Step |

| Diameter (in):4.5" (4-5) |

| Grit:60 (60) |

| Brand:Walter (walter) |

| Used to Grind:Steel (steel) |

| Packaging Description:10 per each (10-per-each) |