The Walter 15A726 7-inch Xtracut Sanding Disc represents a significant advancement in surface preparation and stock removal technology. Engineered by Walter Surface Technologies, this abrasive disc utilizes a premium self-sharpening ceramic grain structure. Unlike conventional aluminum oxide or zirconia grains that dull over time, ceramic grains are designed to micro-fracture under pressure. This continuous fracturing process exposes fresh, sharp cutting edges throughout the life of the disc, ensuring a consistent and aggressive removal rate from the first pass to the last. This characteristic makes the Xtracut line particularly effective for heavy-duty applications where productivity and speed are paramount.

One of the critical challenges in grinding steel and stainless steel is the management of heat zones. Excessive heat can lead to discoloration, warping, and metallurgical changes in the workpiece. The 15A726 addresses this with integrated cooling agents bonded directly into the abrasive matrix. These agents actively lubricate the cutting interface, significantly reducing friction and heat generation. This "cool cut" technology allows operators to apply the necessary pressure for heavy stock removal without compromising the integrity of the metal surface, thereby reducing the need for secondary rework or cleanup.

Efficiency in industrial environments is measured not just by cutting speed but also by downtime. The Xtracut 15A726 features Walter's Quick-Change (QC) mounting system. This center-mount design allows operators to swap out worn discs in seconds without the need for wrenches or flange nuts. When paired with the appropriate rubber backing pad, the QC system provides a secure, centered lock that minimizes vibration and runout. For MRO professionals and fabrication shops, this translates to seamless transitions between tasks and maximized uptime. The coarse grit specification is ideally suited for weld leveling, edge chamfering, and rapid material reduction on carbon and stainless steels.

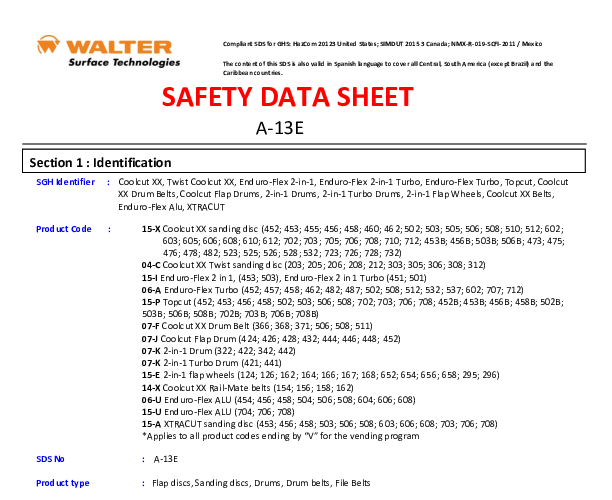

| Additional Information |

|---|

| packaging-description:25 per each |

| ----- new values below ---- |

| Grain Type:Ceramic |

| Mounting System:Quick-Change (QC) |

| Product Line:XTRACUT |

| Application Material:Steel, Stainless Steel |

| Brand:Walter |

| Diameter (in):7" |

| Grit:COARSE |

| Used to Sand:Steel or Stainless |