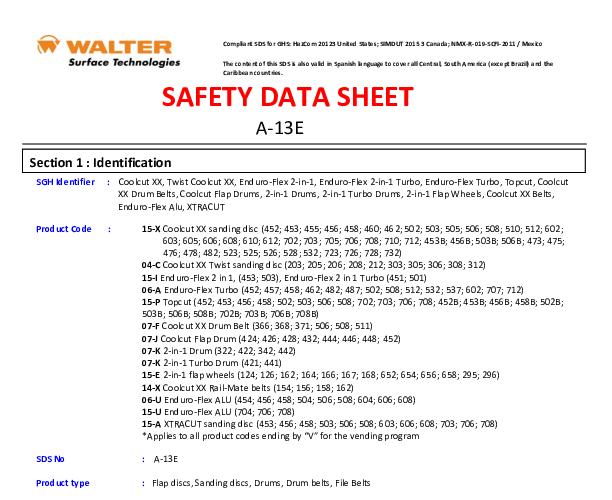

The Walter 15A728 XTRACUT 7-inch sanding disc represents a significant leap forward in abrasive technology for industrial fabrication. Designed to meet the rigorous demands of heavy manufacturing and structural steel work, this disc utilizes a premium self-sharpening ceramic grain structure. Unlike conventional aluminum oxide discs that dull relatively quickly, the ceramic grains in the XTRACUT series are engineered to micro-fracture under pressure. This continuous fracturing process exposes fresh, sharp cutting edges throughout the life of the disc, ensuring that the material removal rate remains consistent from the first pass to the last. For facility managers and procurement specialists, this translates to fewer disc changes and higher throughput per operator hour.

Efficiency is further enhanced by the innovative Quick-Change (QC) mounting system. In high-volume production environments, the time spent swapping out worn abrasives can accumulate into significant lost productivity. The QC system eliminates the need for locking nuts and wrenches, allowing operators to spin the disc off and on by hand in seconds. This streamlined approach ensures that the focus remains on fabrication rather than tool maintenance. The 7-inch diameter of this specific SKU (15A728) offers a large contact area, making it ideal for smoothing welds, blending surfaces, and removing heavy stock on large workpieces.

Thermal management is a critical factor in abrasive performance, particularly when working with heat-sensitive alloys or when aesthetic finish is a priority. Walter has impregnated the XTRACUT discs with advanced cooling agents that actively reduce friction and heat generation at the grinding interface. This "cool cutting" action prevents the workpiece from overheating, thereby reducing the risk of heat-induced distortion, blueing, or metallurgical changes in the base material. This feature is particularly beneficial when working on stainless steel, where heat control is paramount to maintaining corrosion resistance.

Ultimately, the Walter 15A728 is built for cost-effectiveness. While the initial investment in ceramic technology may be higher than standard abrasives, the extended lifespan and aggressive performance deliver a lower total cost of ownership. By reducing the frequency of disc changes and speeding up the grinding process, the XTRACUT Medium Grit disc provides a tangible return on investment for professional fabrication shops looking to optimize their abrasive consumption.

| Additional Information |

|---|

| packaging-description:25 per each |

| ----- new values below ---- |

| Grain Type:Ceramic |

| Mounting System:Quick-Change (QC) |

| Product Line:XTRACUT |

| brand:Walter |

| diameter-in:7" |

| grit:MEDIUM |

| used-to-sand:Steel or Stainless |