The Walter 04C308 Twist Coolcut XX is engineered for industrial environments where efficiency and material removal rates are paramount. This 3-inch sanding disc utilizes a proprietary blend of high-performance ceramic abrasive grains, designed to fracture and self-sharpen under pressure. This mechanism ensures a consistent cutting action throughout the lifespan of the disc, significantly outperforming traditional aluminum oxide or zirconia alternatives. The inclusion of Walter's Cyclone Technology optimizes the grain distribution and bonding matrix, allowing for aggressive stock removal without excessive heat generation.

Heat management is critical when working with high-value alloys such as stainless steel and aluminum. The Coolcut XX formulation incorporates active grinding agents that lubricate the contact zone, reducing friction and preventing thermal discoloration or warping of the workpiece. This makes the 04C308 an ideal choice for demanding applications in aerospace, food processing equipment manufacturing, and structural fabrication where surface integrity cannot be compromised.

The Twist quick-change fastening system is integral to the product's design, offering a secure and vibration-free connection to the backing pad. This mechanical locking mechanism ensures that the disc remains centered even at high rotational speeds, providing a uniform scratch pattern and reducing operator fatigue. With an 80 grit rating, this disc serves as an excellent intermediate step, capable of leveling light welds while preparing the surface for finer finishing steps. It represents a synthesis of durability, speed, and technical sophistication for the modern metalworker.

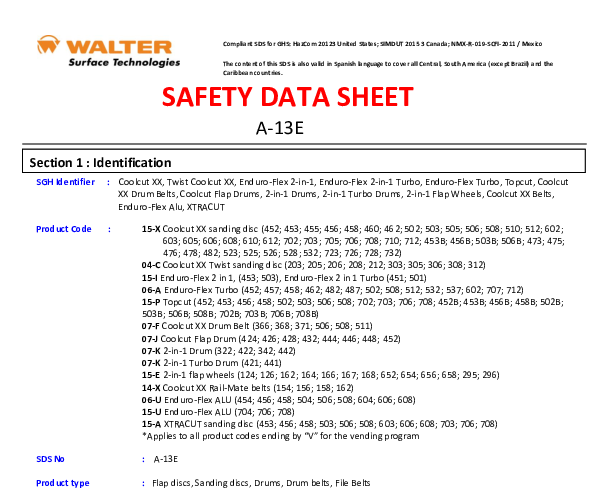

| Additional Information |

|---|

| Packaging Description:50 per each |

| Size (in):3" |

| Grit:80 |

| Used to Sand:Steel or Stainless or Aluminum |

| Abrasive Material:Ceramic Blend |

| Attachment Type:TWIST (Quick-Change) |

| ----- new values below ---- |

| Abrasive Material:Ceramic Blend |

| Attachment Type:Twist (Quick-Change) |

| Product Line:Coolcut XX |

| Brand:Walter |

| Size (in):3" |

| Grit:80 |

| Used to Sand:Steel or Stainless or Aluminum |