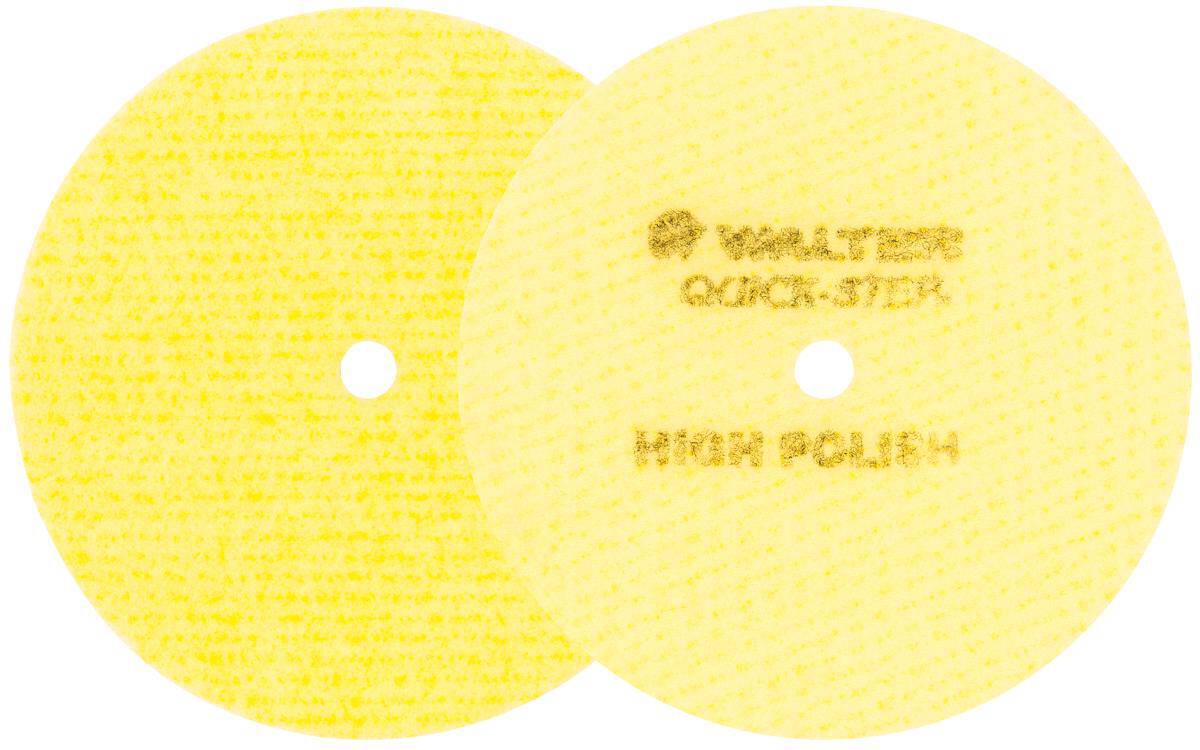

The Walter 07T504 Quick-Step High Polish Disc is a premium abrasive solution engineered for industrial metal finishing applications where aesthetics and surface smoothness are paramount. Designed as the final step in the finishing process, this 5-inch disc is capable of transforming a pre-sanded surface into a brilliant, mirror-like finish. It is particularly effective in industries such as food and beverage processing, pharmaceutical equipment manufacturing, and architectural metalwork, where surface porosity must be minimized to prevent bacterial growth or corrosion.

Integrated into the Walter Quick-Step system, this disc features a hook-and-loop backing that ensures secure attachment to the backing pad while allowing for rapid removal and replacement. This design significantly reduces setup time and facilitates a seamless transition between grit stages. The disc material is optimized to work in conjunction with polishing pastes, effectively carrying the compound to the workpiece without excessive shedding or heat buildup. This thermal management is critical when working with heat-sensitive alloys like stainless steel, preventing discoloration or warping during the final buffing stages.

Operators can rely on the 07T504 for consistent results across a variety of substrates, including aluminum, mild steel, and stainless steel. By utilizing this specialized high-polish disc, fabricators can achieve specified Ra (Roughness Average) values more efficiently than with conventional buffing wheels. Whether upgrading a #4 sanitary finish or restoring a scratched surface to a high gloss, this tool provides the control and performance necessary for high-stakes industrial finishing.

For optimal results, it is recommended to prepare the surface with progressively finer sanding discs before applying the High Polish Disc. The use of a high-quality polishing paste is essential to activate the polishing action of the disc. Ensure the backing pad is centered to minimize vibration and maximize the service life of the abrasive.

| Additional Information |

|---|

| Packaging Description:10 per each |

| Diameter (in):5" |

| Used to Sand:Steel or Stainless or Aluminum |

| System:Quick-Step |

| Application Type:Mirror Finishing, Polishing |

| Mounting Type:Hook and Loop |

| ----- new values below ---- |

| System:Quick-Step |

| Application Type:Mirror Finishing, Polishing |

| Mounting Type:Hook and Loop |

| brand:walter |

| diameter-in:5 |

| used-to-sand:steel-or-stainless-or-aluminum |