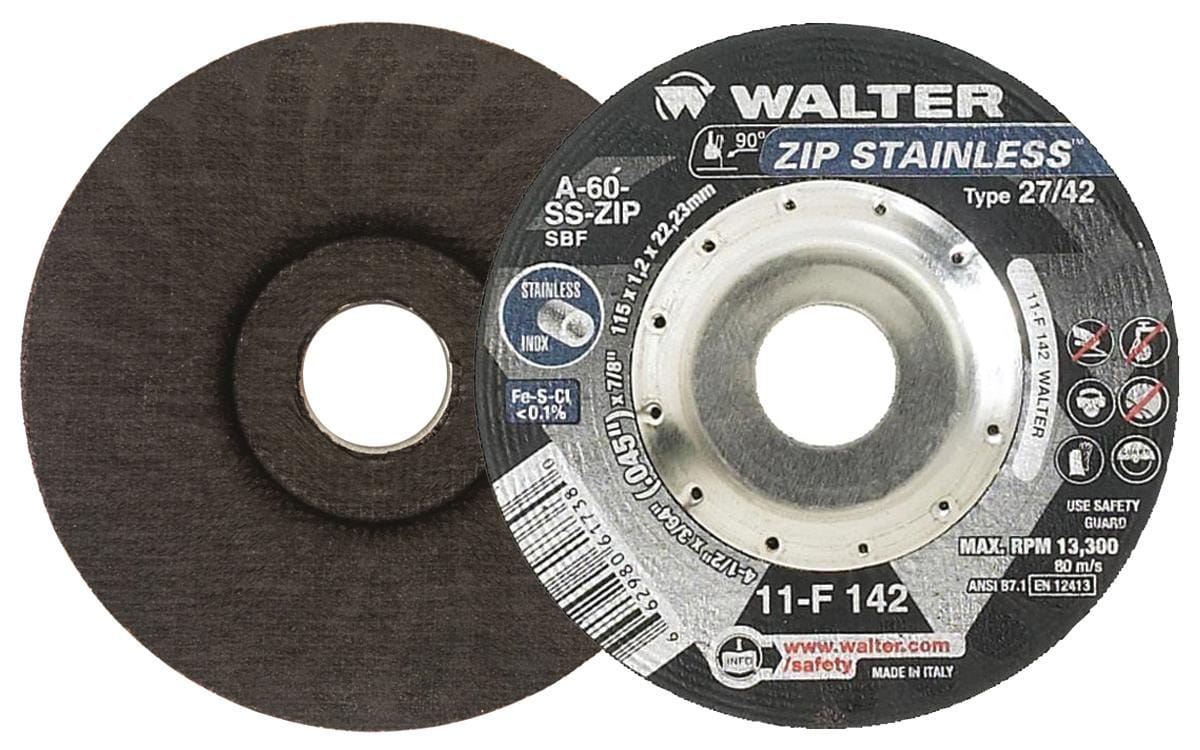

The Walter ZIP Stainless formulation is a pinnacle of abrasive engineering, designed specifically to address the unique challenges of working with stainless steel and nickel alloys. The 11F142 model features a Type 27 depressed center profile, which distinguishes it from standard flat cutting wheels. This geometry allows the locking nut to be recessed within the wheel's center, enabling operators to perform flush cuts and work in tighter constraints without the mounting hardware interfering with the workpiece. This structural advantage is combined with Walter's renowned abrasive technology to deliver superior results in industrial environments.

Contamination is a critical concern in industries such as food processing, pharmaceuticals, and nuclear energy. The ZIP Stainless wheel is manufactured to be free of iron, sulfur, and chlorine (Fe-S-Cl free), ensuring that the cutting process does not introduce impurities that could lead to intergranular corrosion or rust on the stainless surface. By maintaining the chemical integrity of the base material, this wheel reduces the need for extensive post-weld cleaning or passivation, streamlining the fabrication workflow.

Thermal management is another key benefit of this 3/64-inch ultra-thin wheel. The thin profile removes less material, resulting in significantly less friction and heat generation compared to thicker standard wheels. This "cool cutting" action preserves the mechanical properties of the metal and minimizes the Heat Affected Zone (HAZ), which is particularly important for thin-gauge stainless steel to prevent warping or discoloration. The result is a clean, precise cut with minimal burr formation.

Durability is not sacrificed for speed. The reinforced structure of the ZIP Stainless wheel ensures it can withstand the lateral forces often encountered during manual cutting operations, providing a safe and reliable tool for professional fabricators. Whether cutting pipe, sheet metal, or structural profiles, the 11F142 delivers consistent performance that professionals trust.

| Additional Information |

|---|

| Packaging Description:25 per each |

| Diameter (in):4.5" |

| Thickness (in):.045 |

| Used to Cut:Stainless |

| Application Material:Nickel Alloys, Stainless Steel |

| ----- new values below ---- |

| Wheel Type:Type 27 (Depressed Center) |

| Exact Thickness:3/64" |

| Contaminant Free:Yes (Fe, S, Cl < 0.1%) |

| Application Material:Stainless Steel, Nickel Alloys |

| brand:Walter |

| diameter-in:4.5" |

| thickness-in:.045 |

| used-to-cut:Stainless |