The Walter ZIP TiTAN™ 11H042 is a high-performance cutting wheel engineered specifically to address the unique challenges of working with titanium and brass. In industrial MRO and fabrication environments, cutting these materials with standard abrasives often leads to disastrous results, including overheating, material discoloration, and rapid wheel loading. The ZIP TiTAN™ utilizes a proprietary formulation that prevents the wheel from gumming up, ensuring a consistent, free-cutting action that maintains the integrity of the base material.

Titanium is notoriously heat-sensitive, and excessive thermal transfer during cutting can alter its mechanical properties or create a brittle "alpha case" layer. The ZIP TiTAN™ is designed to cut cool, significantly reducing the heat affected zone (HAZ). This is critical for aerospace, petrochemical, and marine applications where the structural integrity of the alloy cannot be compromised. Similarly, when cutting brass, the wheel's composition resists the tendency of the soft metal to adhere to the abrasive grain, preventing the glazing that renders standard wheels useless.

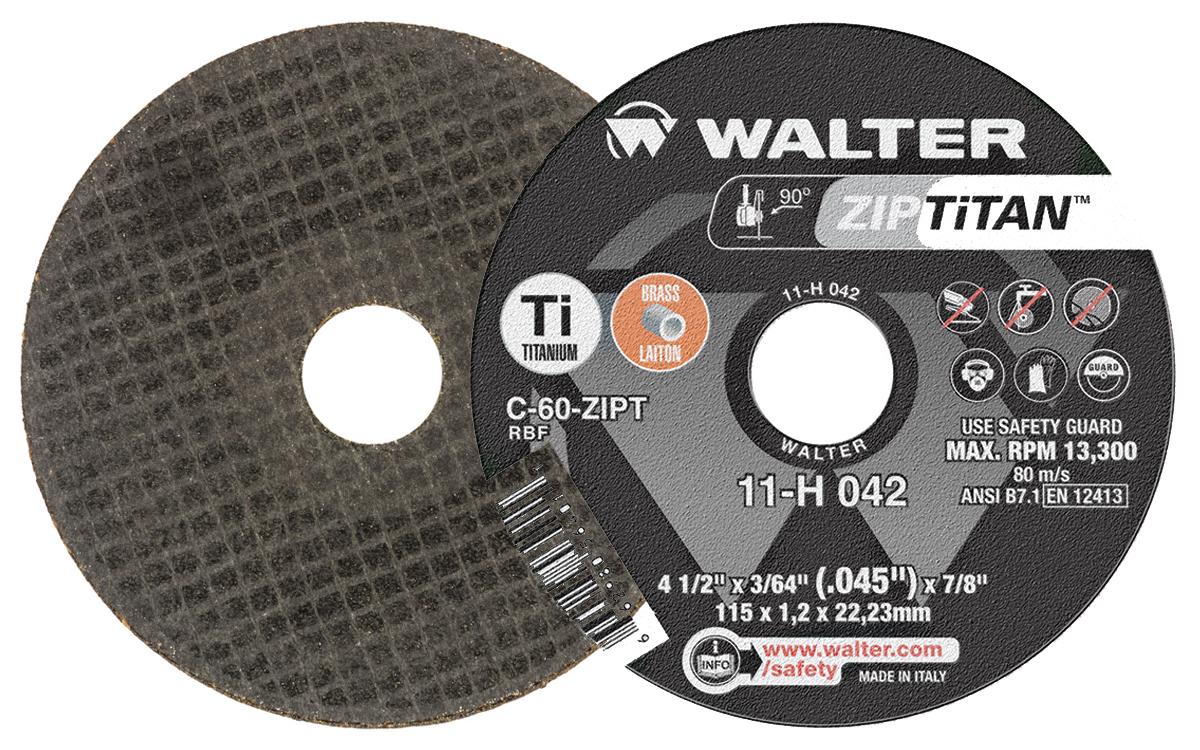

Measuring 4-1/2 inches in diameter with an ultra-thin 3/64-inch thickness, this Type 1 wheel minimizes material loss—a crucial factor when working with expensive exotic metals. The thin kerf also reduces the machine load, allowing for faster cuts with less operator fatigue. Despite its thin profile, the wheel is heavily reinforced for safety and durability, delivering an impressive number of cuts per wheel to lower overall production costs.

Walter Surface Technologies has developed this wheel to meet the rigorous demands of heavy industry. Whether you are fabricating custom titanium piping, repairing brass marine fittings, or working with specialized alloys, the 11H042 provides the reliability and finish quality required for professional results. It is compatible with standard 4-1/2" angle grinders using a 7/8" arbor.

| Additional Information |

|---|

| Packaging Description:25 per box, 25 per each |

| Diameter (in):4.5" |

| Thickness (in):3/64" |

| Arbor (in):7/8" |

| Used to Cut:Alloys, Brass, Titanium |

| Max RPM:13300 |

| ----- new values below ---- |

| Wheel Type:Type 1 |

| Max RPM:13300 |

| Bond Type:Resinoid |

| Reinforcement:Fiberglass |

| Diameter (in):4.5" |

| Thickness (in):3/64" |

| Arbor (in):7/8" |

| Brand:Walter |

| Used to Cut:Titanium, Brass, Alloys |

| Packaging Description:25 per box |