In high-stakes industries such as aerospace, petrochemical, and marine manufacturing, the integrity of the base material is paramount. The Walter ZIP TiTAN™ 11H062 is a specialized abrasive cutting wheel engineered to address the unique challenges of working with titanium and brass. Standard abrasive wheels often generate excessive friction when cutting these materials, leading to dangerous overheating, discoloration, and the alteration of the metal's mechanical properties. The ZIP TiTAN formulation is designed to cut cool and free, ensuring that the structural integrity of your workpiece is maintained throughout the fabrication process.

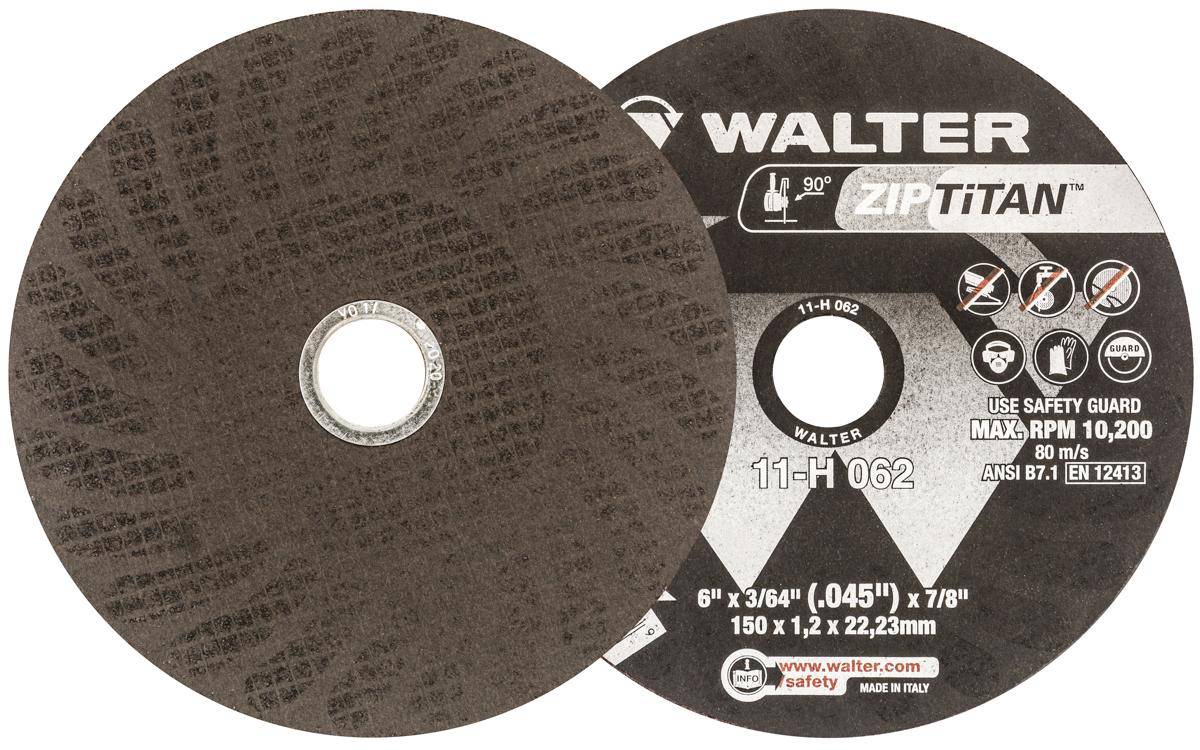

This 6-inch wheel features a thin 3/64" profile, which minimizes the surface area in contact with the metal. This design significantly reduces friction and material loss, resulting in a cleaner, faster cut that requires less energy from the power tool. For facility managers and procurement specialists, the ZIP TiTAN represents a cost-effective solution; its superior durability means fewer wheel changes and less downtime, translating to higher throughput in production environments. The wheel is reinforced for safety, meeting the rigorous demands of industrial applications while providing consistent performance from the first cut to the last.

Whether you are cutting titanium sheets for vessel cladding or trimming brass fittings, the 11H062 delivers precision and reliability. It effectively prevents the glazing issues common with general-purpose wheels on soft or gummy metals, ensuring the abrasive grains remain exposed and active. By choosing the ZIP TiTAN, you are investing in a consumable that protects your expensive raw materials and enhances the overall quality of your finished products.

| Additional Information |

|---|

| Packaging Description:25 per box, 25 per each |

| Diameter (in):6" |

| Thickness (in):3/64" |

| Arbor (in):7/8" |

| Used to Cut:Brass, Titanium |

| Max RPM:10200 |

| Material Application:Brass, Bronze, Titanium, Zirconium |

| ----- new values below ---- |

| Wheel Type:Type 1 |

| Max RPM:10,200 |

| Material Application:Titanium, Brass, Bronze, Zirconium |

| Diameter (in):6" |

| Thickness (in):3/64" |

| Arbor (in):7/8" |

| Used to Cut:Titanium, Brass |

| Brand:Walter |

| Packaging Description:25 per box |