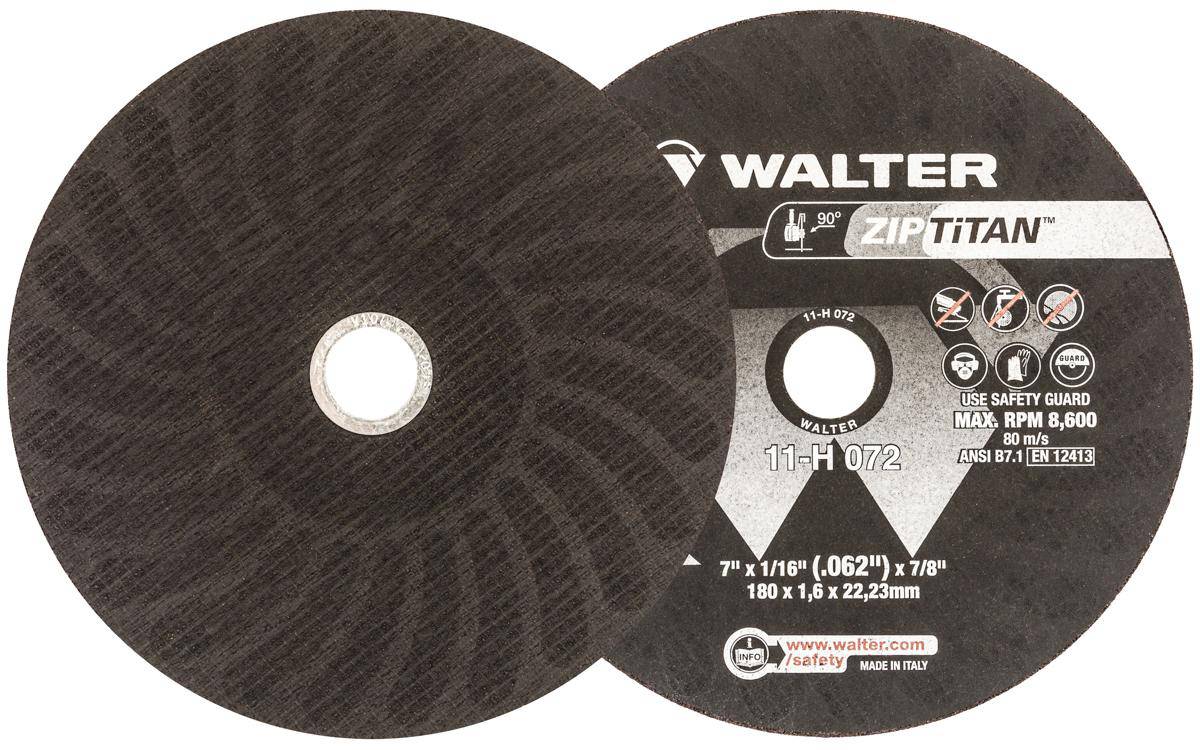

The Walter ZIP TITAN™ 7" x 1/16" Cutting Wheel (SKU: 11H072) represents a significant advancement in abrasive technology, specifically engineered to address the unique challenges of working with titanium and brass. In industrial manufacturing, maintenance, and fabrication, these materials present distinct difficulties: titanium is notoriously heat-sensitive and prone to work-hardening, while brass is softer and tends to "gum up" or load standard abrasive wheels. The ZIP TITAN™ formulation is the ultimate solution, designed to slice through these metals effortlessly while maintaining the highest standards of surface integrity.

One of the critical features of this wheel is its cool-cutting capability. When cutting titanium, excessive heat generation can lead to the "alpha case" layer or discoloration, which compromises the material's structural properties. The ZIP TITAN™ is manufactured with a unique blend of abrasive grains and bonding agents that significantly reduce friction and heat transfer. This ensures that the mechanical properties of the titanium remain unaffected, reducing the need for secondary rework or grinding to remove heat-affected zones. For brass applications, the wheel's structure resists loading, ensuring consistent cutting speed throughout the life of the wheel.

Durability and efficiency are at the core of the Walter ZIP family. This 7-inch wheel offers extended life and more cuts per unit compared to general-purpose abrasives used on these specific materials. By minimizing wheel changes and maximizing cutting speed, the ZIP TITAN™ improves overall workflow efficiency. It is an essential tool for industries such as aerospace, marine, petrochemical, and power generation where titanium and brass alloys are frequently utilized. Safety is also paramount; the wheel is heavily reinforced to withstand the stresses of high-speed cutting while providing a smooth, vibration-free experience for the operator.

Incorporating the ZIP TITAN™ into your abrasive inventory ensures that your facility is equipped to handle exotic alloys with precision. It eliminates the guesswork and inefficiencies associated with using standard steel cutting wheels on specialized materials, delivering professional, high-quality results every time.

| Additional Information |

|---|

| Packaging Description:25 per each |

| Diameter (in):7" |

| Thickness (in):1/16 |

| Arbor (in):7/8" |

| Used to Cut:Alloys, Brass, Titanium |

| Max RPM:8600 |

| Application Material:Brass, Titanium |

| ----- new values below ---- |

| Wheel Type:Type 1 |

| Max RPM:8600 |

| Application Material:Titanium, Brass |

| Brand:Walter |

| Diameter (in):7" |

| Thickness (in):1/16 |

| Arbor (in):7/8" |

| Used to Cut:Titanium, Brass, Alloys |