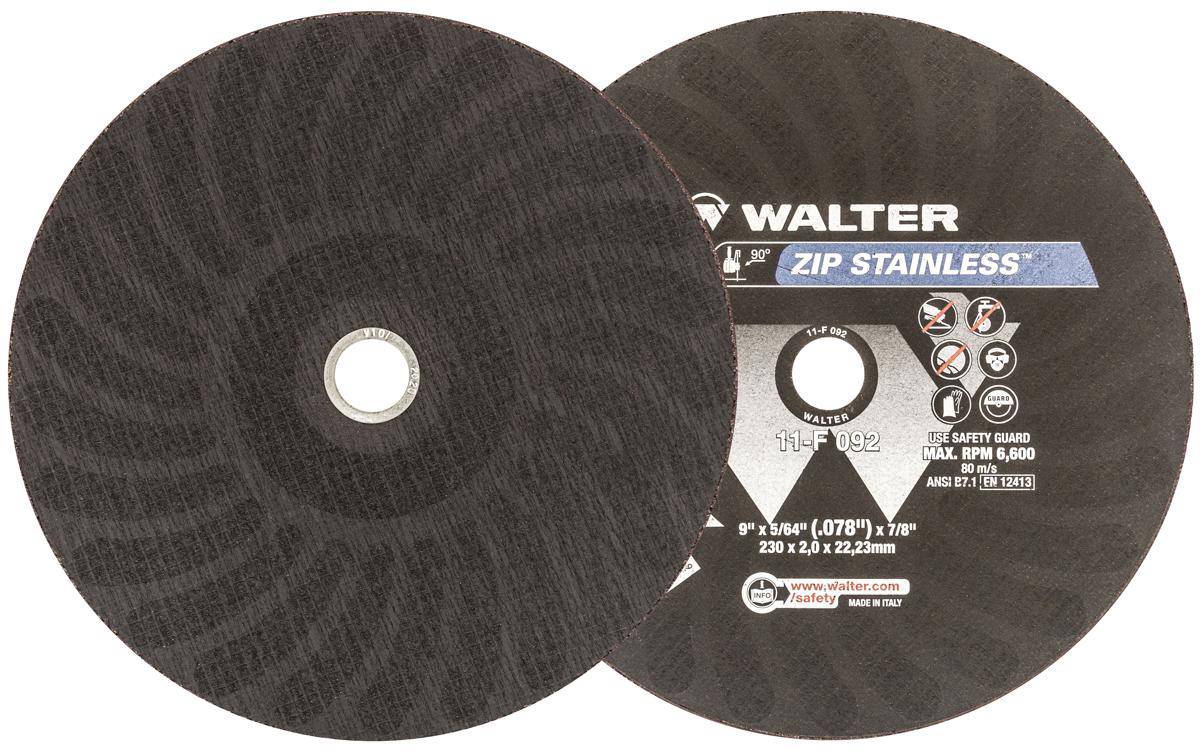

The Walter ZIP Stainless cutting wheel (SKU: 11F092) represents the pinnacle of abrasive technology for large-scale fabrication. Designed specifically for the unique demands of stainless steel and nickel alloyed steels, this 9-inch wheel is a staple in workshops where material integrity is paramount. Unlike general-purpose abrasives that may leave behind contaminants, the ZIP Stainless is engineered to be completely free of iron, sulfur, and chlorine. This ensures that your stainless steel projects remain rust-free and maintain their corrosion-resistant properties long after the cut is made.

Measuring 9 inches in diameter with a thin 5/64-inch profile, this wheel is built for speed and efficiency on heavy-duty angle grinders. The thin kerf allows the wheel to slice through metal with less resistance, generating significantly less friction and heat. This "cool cutting" capability is critical when working with heat-sensitive materials, as it minimizes discoloration and warping, reducing the need for time-consuming post-weld cleaning or polishing. Whether you are cutting pipe, plate, or structural beams, the ZIP Stainless delivers a smooth, clean cut every time.

Safety and durability are also core features of the Walter 11F092. The wheel is heavily reinforced to withstand the torque and stress of high-speed cutting, providing peace of mind to operators. Its extended lifespan means fewer wheel changes, leading to better productivity and lower overall consumable costs. For fabricators who refuse to compromise on quality, the Walter ZIP Stainless is the trusted choice for achieving precise, burr-free cuts on the toughest alloys.

| Additional Information |

|---|

| Packaging Description:25 per box, 25 per each |

| Diameter (in):9" |

| Thickness (in):5/64" |

| Arbor (in):7/8" |

| Used to Cut:Stainless |

| Max RPM:6600 |

| Material Composition:Fe-S-Cl Free |

| ----- new values below ---- |

| Max RPM:6600 |

| Wheel Type:Type 1 |

| Material Composition:Fe-S-Cl Free |

| Brand:Walter |

| Diameter (in):9" |

| Thickness (in):5/64" |

| Arbor (in):7/8" |

| Used to Cut:Stainless |

| Packaging Description:25 per box |