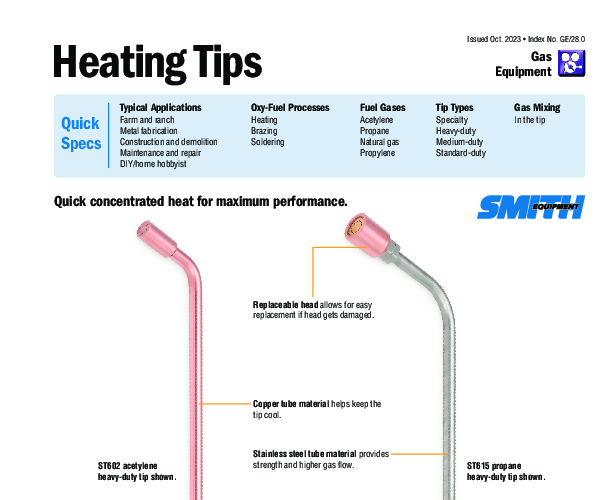

The Miller Smith ST615 Heavy Duty Heating Tip is a premium oxy-fuel component designed for industrial professionals requiring substantial heat output without the operational costs associated with acetylene. Engineered to operate efficiently with alternate fuel gases including Propane, Natural Gas, and Propylene, this tip assembly provides exceptional versatility and economy for a wide range of heating applications. With a robust construction typical of the Smith Equipment legacy, now under the Miller Electric umbrella, the ST615 ensures durability and consistent performance in the most demanding environments, from shipyards to structural steel fabrication plants.

Technically, the ST615 distinguishes itself with a specialized fluted flame design. Unlike standard single-orifice tips, the fluted configuration optimizes the combustion of alternate fuels, which burn at different velocities compared to acetylene. This design ensures a stable, wind-resistant flame that delivers a concentrated and powerful heat source. The thermal output is impressive, capable of generating approximately 244,000 BTU/hr with Propane, 155,145 BTU/hr with Natural Gas, and up to a staggering 280,000 BTU/hr with Propylene. Such high thermal density makes it an excellent choice for preheating heavy plate prior to welding, bending large diameter pipes, straightening warped structural members, and other fabrication tasks where rapid heat transfer is essential to maintain workflow efficiency.

The ST615 is specifically engineered to interface seamlessly with Smith Equipment WH200 and SW1B torch handles. Its substantial 15-3/4 inch length provides ample reach, a critical safety feature that helps to keep the operator and the torch handle mechanism away from the intense reflected heat of the workpiece. This extension reduces the risk of handle overheating and improves operator comfort during prolonged heating cycles. Safety is paramount when dealing with such high-volume gas flow; therefore, it is strongly recommended—and often necessary—to use this tip in conjunction with high-flow flashback arrestors. Standard arrestors may restrict flow, starving the tip and causing instability. Furthermore, due to the high volume of gas required for maximum BTU output, users must ensure their fuel supply is adequate. For Propane, a 100lb cylinder is often required for continuous operation at 70 degrees Fahrenheit to prevent the tank from "freezing" due to the rapid vaporization rate required.

Constructed from high-quality copper and brass alloys, the ST615 is built to withstand the thermal cycling and physical abuse common in heavy industry. The tip face is recessed to protect the orifices from damage if accidentally bumped against the workpiece, ensuring a long service life. By integrating the Miller Smith ST615 into your equipment inventory, you leverage the cost benefits of readily available alternate fuels while maintaining the high-performance standards required for heavy industrial MRO and fabrication.

| Additional Information |

|---|

| Fuel Gas:Natural Gas, Propane, propylene |

| Item:Heat Tip |

| Fits Which Handle?:SW1B, WH200 |

| Weld Cap or btu/hr:155,000 - 280,000 BTU/hr |

| Length :15-3/4 inches |

| Flame Type:Fluted |

| Size:Heavy Duty (HD) |

| ----- new values below ---- |

| Length:15-3/4 inches |

| Flame Type:Fluted |

| Size:Heavy Duty (HD) |

| Required Cylinders:1-2 Fuel Cylinders, 100lb Propane Tank |

| Brand:Miller Smith |

| Fuel Gas:Propane, Natural Gas, Propylene |

| Item:Heat Tip |

| Fits Which Handle?:WH200, SW1B |

| Weld Cap or btu/hr:155,000 - 280,000 BTU/hr |