The Miller 20 Series Argon/CO2 Flowmeter Regulator (22-80-580) represents a significant advancement in shielding gas regulation technology, designed specifically to address common failure points in industrial welding environments. At the core of this device is Miller's exclusive Sure Seat™ filtered high-pressure seat assembly. In standard regulators, debris and contamination from the cylinder are the leading causes of seat failure and regulator creep. The Sure Seat™ technology integrates a filtration system directly into the seat assembly, preventing particulate matter from entering the critical seating area. This engineering choice significantly extends the lifespan of the regulator, reduces maintenance downtime, and minimizes the frequency of costly repairs.

Accuracy in gas delivery is paramount for maintaining weld quality and controlling consumable costs. The 22-80-580 features a unique self-centering flowball within its flow tube. Conventional flowmeters often rely on a ball that can float off-center if the cylinder or regulator is slightly tipped, leading to readings that can deviate by up to 2.5 times the actual flow. Miller's self-centering design ensures the ball remains perfectly aligned within the gas stream, providing precise flow readings regardless of minor orientation shifts. This precision allows facility managers and welding engineers to set exact flow rates (10-80 SCFH) without the buffer of "safety margins" that waste expensive Argon or CO2 gas.

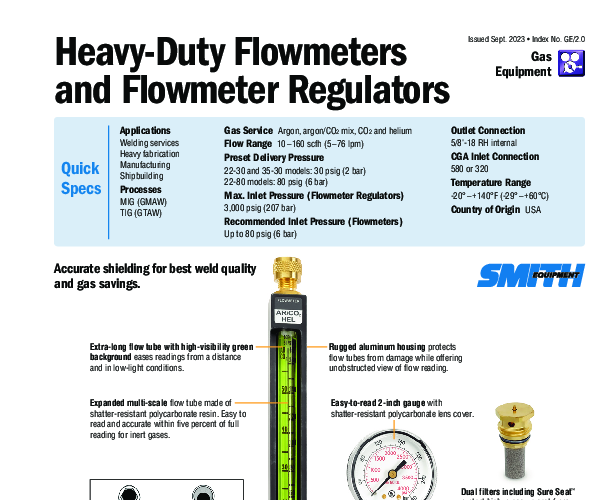

Constructed for the rigors of heavy-duty industrial use, the regulator body is housed in rugged aluminum, offering substantial protection against the accidental impacts common on busy shop floors. The flow tube itself is manufactured from shatter-resistant polycarbonate resin, a material chosen for its high impact strength and optical clarity. The unit is calibrated for a preset outlet pressure of 80 PSIG and connects via a standard CGA 580 inlet, making it compatible with standard inert gas cylinders. Safety is further reinforced by an auto-reset pressure-relief valve, which vents excessive pressure in the event of a surge and automatically resets, protecting both the equipment and the operator.

For MRO specialists seeking a reliable, low-maintenance solution for MIG and TIG welding stations, the Miller 22-80-580 offers a blend of durability, filtration technology, and measurement accuracy that outperforms standard competitive units.

| Additional Information |

|---|

| Packaging Description:1 Per Ea |

| Gas Type:Argon, CO2 |

| Flow Range:10-80 SCFH |

| Inlet Connection:CGA 580 |

| Series:20 Series |

| Warranty:3 Year True Blue |

| ----- new values below ---- |

| Gas Type:Argon, CO2 |

| Flow Range:10-80 SCFH |

| Inlet Connection:CGA 580 |

| Outlet Pressure:80 PSIG |

| Series:20 Series |

| Housing Material:Aluminum |

| Flow Tube Material:Polycarbonate Resin |

| Warranty:3 Year True Blue |

| Brand:Miller Electric |

| Packaging Description:1 Per Ea |