The Miller 20 Series Argon/CO2 Flowmeter Regulator (22-80-580-6) is an industrial-grade gas control device engineered for durability and precision in MIG and TIG welding environments. Designed to handle high-pressure cylinders up to 3000 PSIG, this unit provides accurate flow regulation up to 80 SCFH, making it suitable for a wide range of fabrication tasks. The assembly includes a 6-foot gas hose, ensuring immediate compatibility with standard welding setups utilizing CGA 580 connections.

At the core of the 20 Series is Miller’s exclusive Sure Seat™ filtered seat technology. In industrial environments, debris and particulate matter from cylinders can compromise the seating area of a regulator, leading to pressure creep, leaks, and premature failure. The Sure Seat™ system integrates a high-efficiency filter that prevents contamination from entering the high-pressure seat assembly. This design not only extends the service life of the regulator but also significantly reduces maintenance downtime and repair costs. Additionally, the filtered seat design helps mitigate CO2 freeze-up issues, ensuring consistent performance during extended welding sessions.

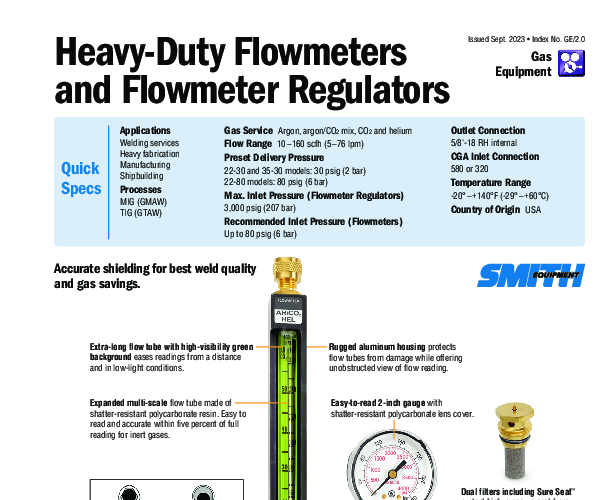

Traditional flowmeters rely on gravity and perfect vertical alignment for accurate readings. The Miller 20 Series utilizes a unique self-centering flow ball guide. This engineering innovation ensures that the ball remains centered within the flow tube, providing precise flow readings even if the cylinder or regulator is tipped off-axis. By preventing the ball from floating off-center—which can cause actual gas flow to be up to 2.5 times greater than indicated—this feature directly contributes to gas savings and optimal weld quality.

Built for the shop floor, the flowmeter features a rugged aluminum housing that shields the flow tube from accidental impact. The tube itself is constructed from shatter-resistant polycarbonate resin, offering superior durability compared to traditional glass tubes. The scale features a high-visibility green background, allowing operators to easily monitor gas flow from a distance or in low-light conditions. An auto-reset pressure-relief valve provides an added layer of safety by venting excessive pressure surges and automatically resetting, protecting the internal components from damage.

| Additional Information |

|---|

| Packaging Description:1 Per Ea, pack of 1 |

| Gas Type:Argon, CO2 |

| Flow Range:0-80 SCFH |

| Inlet Connection:CGA 580 |

| Hose Length:6 ft |

| Series:20 Series |

| Material:Aluminum Housing, Polycarbonate Flow Tube |

| ----- new values below ---- |

| Gas Type:Argon, CO2 |

| Flow Range:0-80 SCFH |

| Inlet Connection:CGA 580 |

| Hose Length:6 ft |

| Max Inlet Pressure:3000 PSIG |

| Series:20 Series |

| Material:Polycarbonate Flow Tube, Aluminum Housing |

| Brand:Miller Electric |

| Packaging Description:pack of 1 |