The Miller Smith 210-40-10 Silverline High Purity Analytical Single Stage Regulator is engineered for professionals who demand exacting standards in gas delivery. Designed specifically for non-corrosive specialty gases, this regulator is a staple in laboratory environments, automotive emissions testing facilities, and chemical process plants. The core of its performance lies in its ability to maintain gas purity; the materials of construction are carefully selected to ensure they do not contaminate the gas stream. This makes it an ideal choice for sensitive instrumentation where even microscopic impurities can skew results.

At the heart of the 210 Series is a stainless steel diaphragm. Unlike neoprene or rubber diaphragms found in standard industrial regulators, stainless steel provides a non-permeable barrier that prevents the inboard diffusion of atmospheric contaminants. This feature is critical for maintaining the integrity of high-purity gases. Furthermore, the regulator is equipped with a filtered seat, which not only enhances gas stream purity but also extends the service life of the unit by preventing debris from damaging the seating surface. The body and bonnet are constructed from rugged brass bar stock, which is then plated. This plating offers superior protection against environmental corrosion and maintains a clean, professional appearance suitable for laboratory settings.

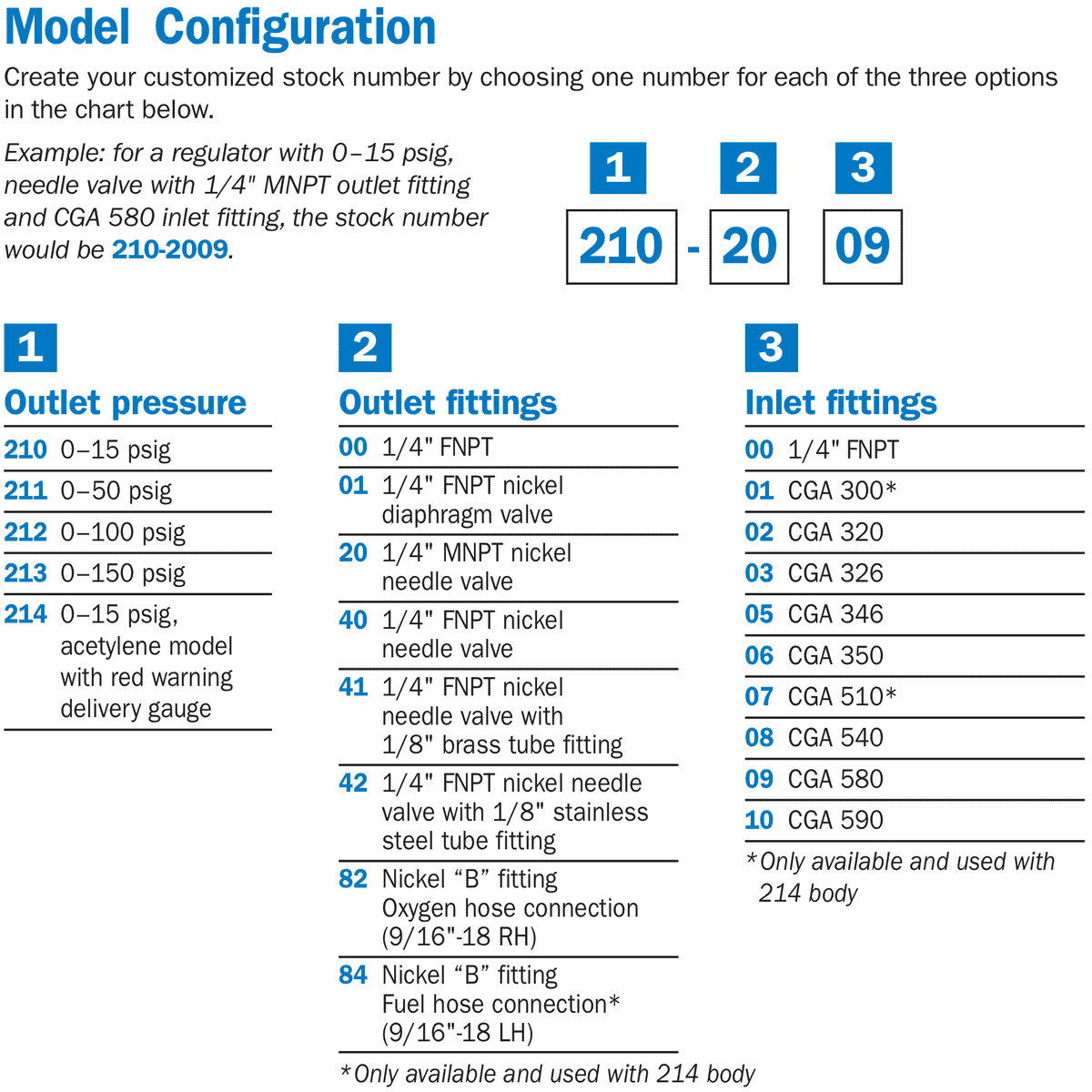

Safety and ease of use are paramount in the design of the Miller Smith 210-40-10. The unit features large, 2-1/2 inch single-scale gauges that are easy to read, allowing operators to monitor cylinder and delivery pressure at a glance. The regulator is capable of withstanding vacuums generated during purging operations, a common procedure in high-purity gas handling to eliminate cross-contamination. Additionally, a built-in capturable preset safety relief valve provides an added layer of protection against over-pressurization. With a maximum inlet pressure of 3500 PSIG and a precise delivery range of 0-15 PSIG, this regulator offers the control needed for delicate low-pressure applications. The CGA 590 connection ensures compatibility with specific industrial air and specialty gas cylinders.

| Additional Information |

|---|

| Packaging Description:1 Per Ea, 1 per each |

| CGA Fitting:cga590 |

| Item:Regulator |

| Max Inlet:3500psi |

| Max Outlet:15psi |

| Used On Which Gas:Industrial Air |

| Gas Type:Industrial Air, Specialty Gas |

| Connection Type (CGA):CGA 590 |

| Inlet/Outlet Pressure:Delivery: 0-15 PSIG, Max Inlet: 3500 PSIG |

| Gauge Type:2-1/2" Single Scale |

| Body Material:Plated Brass |

| Diaphragm Material:Stainless Steel |

| Series:210 Silverline |

| ----- new values below ---- |

| Gas Type:Specialty Gas, Industrial Air |

| Connection Type (CGA):CGA 590 |

| Inlet/Outlet Pressure:Max Inlet: 3500 PSIG, Delivery: 0-15 PSIG |

| Gauge Type:2-1/2" Single Scale |

| Body Material:Plated Brass |

| Diaphragm Material:Stainless Steel |

| Series:210 Silverline |

| Brand:Miller |

| CGA Fitting:cga590 |

| Item:Regulator |

| Max Inlet:3500psi |

| Max Outlet:15psi |

| Used On Which Gas:Industrial Air |

| Packaging Description:1 per each |