The Miller Smith 220-20-03 Silverline High Purity Analytical Two Stage Regulator is engineered to meet the rigorous demands of laboratory and analytical environments. Designed specifically for high purity, non-corrosive pure gases and mixtures, this regulator ensures the integrity of your gas stream is maintained from the cylinder to the instrument. It is ideally suited for controlling carrier gases or calibration mixtures used in gas chromatography, including thermal conductivity, flame ionization, flame photometry, and electron capture applications.

At the core of this regulator is a stainless steel diaphragm that provides precise pressure control and prevents contamination of the gas stream. Unlike standard rubber diaphragms, the stainless steel construction eliminates off-gassing and permeation, ensuring that the purity of your analytical gases remains uncompromised. The regulator also features a filtered seat, which not only contributes to gas stream purity but also significantly extends the service life of the unit by preventing particulate damage to the seating surface.

The two-stage design of the 220 Series is critical for applications requiring unwavering stability. By reducing cylinder pressure in two steps, the regulator maintains a constant delivery pressure of 0-15 PSI regardless of fluctuations in the supply cylinder pressure. This means you can utilize the full content of your gas cylinders without experiencing the "decay" in pressure common with single-stage regulators as the cylinder empties. This feature is essential for long-duration analytical runs where pressure stability directly correlates to data accuracy.

Built from rugged brass bar stock, the body, bonnet, and gauges are fully plated to offer superior protection against corrosion and to maintain a clean, professional appearance suitable for laboratory settings. The regulator is equipped with large, 2-1/2 inch single-scale gauges that are easy to read, allowing for quick verification of cylinder and delivery pressures. Safety is paramount, and the unit includes a built-in capturable preset safety relief valve to protect downstream components from over-pressurization. Additionally, the design is robust enough to withstand vacuums generated during purging operations, making it a versatile tool for complex gas management systems.

| Additional Information |

|---|

| Gas Type:High Purity, Specialty Gas |

| Stage Type:Two Stage |

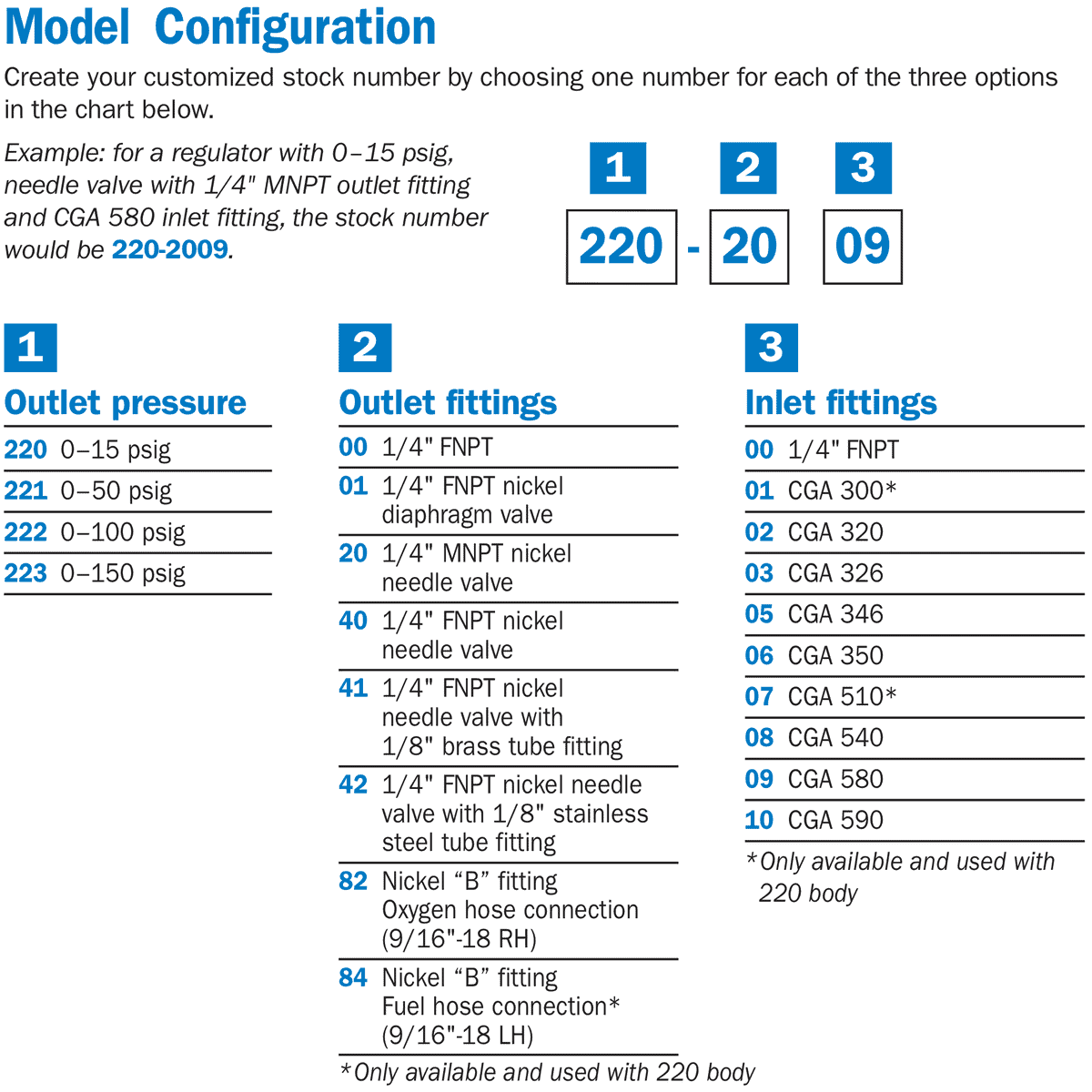

| Inlet Connection:CGA 326 |

| Delivery Pressure Range:0-15 PSI |

| Series:Silverline 220 |

| Diaphragm Material:Stainless Steel |

| Body Material:Plated Brass Bar Stock |

| Outlet Connection:1/4" MNPT Needle Valve |

| ----- new values below ---- |

| Series:Silverline 220 |

| Diaphragm Material:Stainless Steel |

| Body Material:Plated Brass Bar Stock |

| Outlet Connection:1/4" MNPT Needle Valve |

| Gauge Size:2-1/2 Inch |

| Brand:Miller Smith |

| Gas Type:High Purity, Specialty Gas |

| Stage Type:Two Stage |

| Inlet Connection:CGA 326 |

| Delivery Pressure Range:0-15 PSI |

| Max Inlet Pressure:3500 PSI |