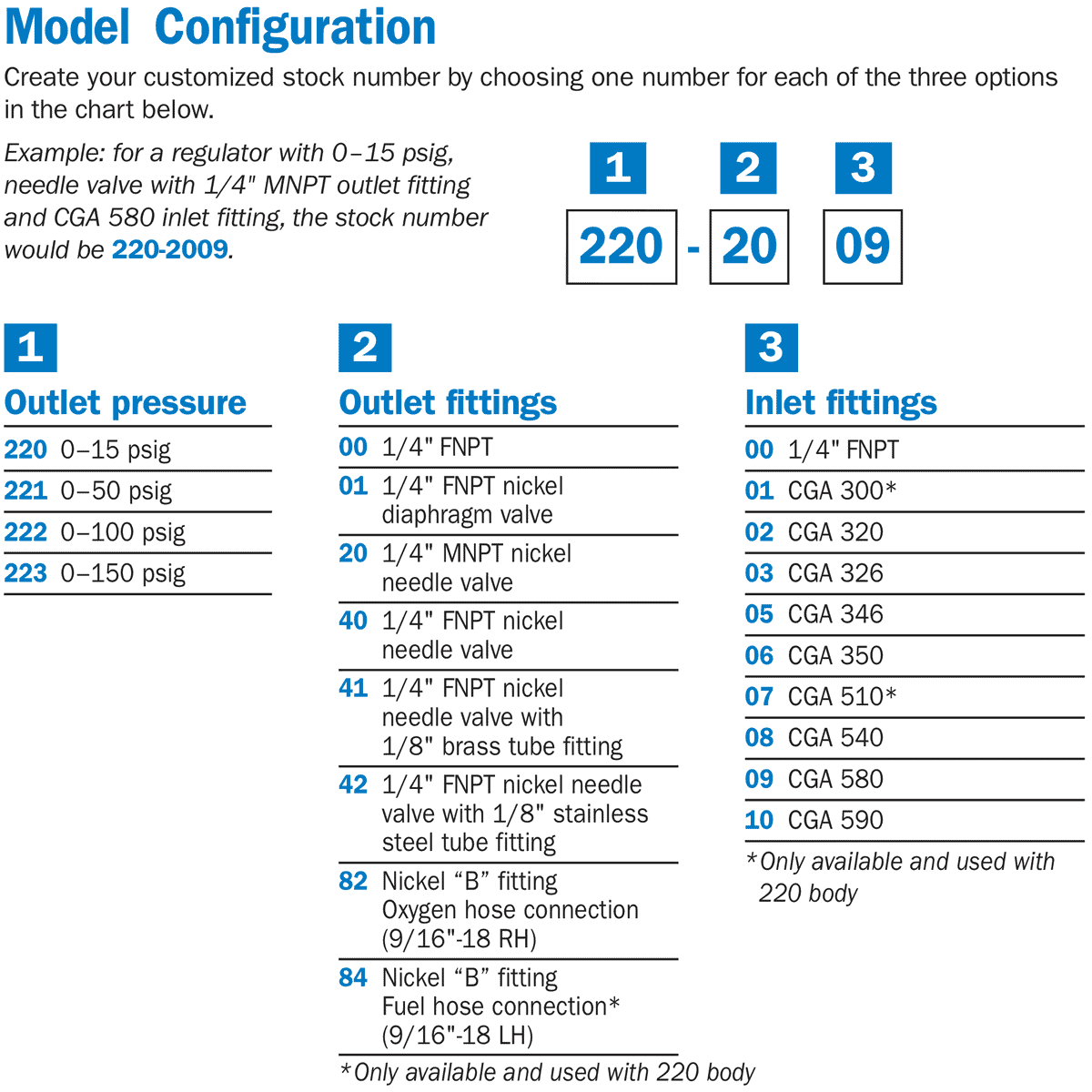

The Miller Smith 221-20-06 Silverline High Purity Analytical Two Stage Regulator is engineered to meet the rigorous demands of laboratory and analytical environments. Designed specifically for non-corrosive, high-purity gases, this regulator is an essential tool for applications requiring absolute stability and cleanliness, such as gas chromatography, thermal conductivity analysis, and flame ionization. The unit features a CGA 350 inlet connection, making it suitable for hydrogen, methane, and other compatible flammable gas mixtures often used in carrier gas applications.

At the heart of the 221-20-06 is a stainless steel diaphragm that ensures precise control over delivery pressure while maintaining the integrity of the gas stream. Unlike rubber or neoprene diaphragms, stainless steel prevents off-gassing and contamination, which is critical when working with calibration mixtures where even parts-per-billion levels of impurities can skew results. The regulator also incorporates a filtered seat mechanism that traps particulates, further enhancing gas purity and extending the service life of the internal components.

Analytical processes often run for extended periods, requiring a consistent flow of gas as the supply cylinder depletes. This regulator utilizes a two-stage design, which steps down the pressure in two increments. This mechanical advantage allows the regulator to maintain a constant delivery pressure of 0-50 PSIG regardless of fluctuations in the cylinder's inlet pressure. Whether the cylinder is full at 3500 PSI or nearing empty, your instrument receives a steady, reliable flow, eliminating the need for constant manual adjustments.

Safety is paramount when handling high-pressure specialty gases. The Miller Smith 221-20-06 includes a built-in capturable preset safety relief valve that protects downstream equipment from over-pressurization. The body, bonnet, and gauges are plated to resist corrosion and wear, ensuring the device maintains its aesthetic and functional quality over years of service. Additionally, the regulator is designed to withstand vacuums generated during purging operations, a common procedure in high-purity gas handling to eliminate atmospheric contamination before use.

| Additional Information |

|---|

| Packaging Description:1 Per Ea, pack of 1 |

| Series:Silverline 220 |

| Stage Type:Two Stage |

| Gas Service:High Purity, Hydrogen, Methane, Specialty Gas |

| Inlet Connection:CGA 350 |

| Outlet Connection:1/4" MNPT Needle Valve |

| Delivery Pressure Range:0-50 PSIG |

| Diaphragm Material:Stainless Steel |

| Body Material:Plated Brass Bar Stock |

| ----- new values below ---- |

| Series:Silverline 220 |

| Stage Type:Two Stage |

| Gas Service:High Purity, Specialty Gas, Hydrogen, Methane |

| Inlet Connection:CGA 350 |

| Outlet Connection:1/4" MNPT Needle Valve |

| Delivery Pressure Range:0-50 PSIG |

| Max Inlet Pressure:3500 PSIG |

| Diaphragm Material:Stainless Steel |

| Body Material:Plated Brass Bar Stock |

| Brand:Miller OEM |

| Packaging Description:pack of 1 |