In the world of industrial fabrication and supply, material traceability is paramount. The Walter Molybdenum Reagent (54A051) provides a fast, reliable, and cost-effective solution for identifying stainless steel grades, specifically distinguishing between AISI 304 and AISI 316. As supply chains become more complex, the risk of material mix-ups increases. Using the wrong grade of stainless steel in a corrosive environment can lead to catastrophic failure and significant liability. This 100ml reagent bottle is an essential tool for Quality Assurance managers, receiving departments, and shop floor supervisors who need to validate raw materials before processing.

The science behind the reagent is straightforward yet powerful. Molybdenum is the key alloying element that gives 316 stainless steel its superior corrosion resistance compared to the standard 304 grade. When applied to the metal surface, this reagent reacts specifically to the presence of Molybdenum. A positive reaction (typically a color change) confirms the presence of Molybdenum, indicating the material is likely 316 grade. A lack of reaction suggests the absence of Molybdenum, pointing towards 304 grade. This simple spot test eliminates the guesswork and provides immediate visual confirmation.

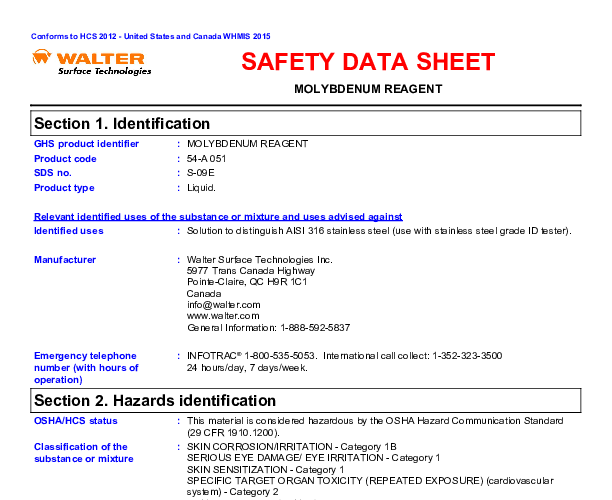

Designed for professional industrial use, the Walter 54A051 comes in a convenient 100ml bottle, sufficient for hundreds of individual tests. It is a non-destructive testing (NDT) chemical that allows for on-the-spot verification without the need for expensive X-ray fluorescence (XRF) guns or sending samples to external laboratories. Whether you are auditing inventory, checking incoming shipments, or verifying scrap metal, this molybdenum reagent is a critical line of defense against material non-conformance.

| Additional Information |

|---|

| packaging-description:1 per each |

| ----- new values below ---- |

| Volume:100ml |

| Application:Stainless Steel Grade Identification |

| Target Material:Stainless Steel 304, Stainless Steel 316 |

| Brand:Walter |

| Format:Liquid |

| Packaging Description:1 per each |