The Walter Surfox Pre-Weld (54A076) is an advanced chemical solution engineered specifically for the rigorous demands of industrial welding preparation. Achieving a defect-free weld begins long before the arc is struck; it starts with a pristine surface. Contaminants such as cutting fluids, shop oils, grease, and marker ink are the primary culprits behind weld porosity, lack of fusion, and inclusions. Surfox Pre-Weld is formulated to aggressively dissolve and lift these contaminants from metallic surfaces, ensuring optimal base material conditions for TIG, MIG, and stick welding processes.

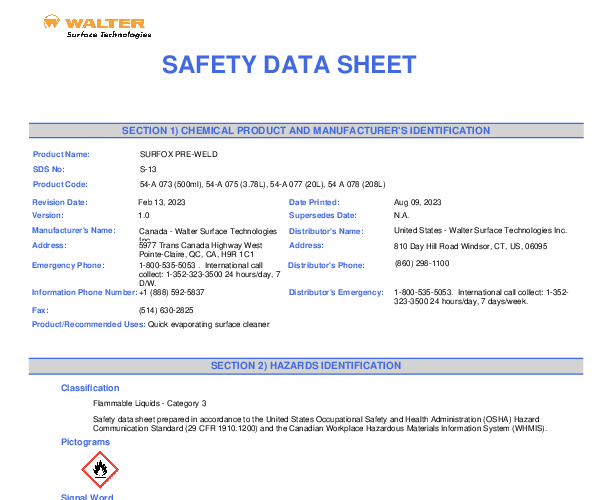

One of the distinguishing technical advantages of this formulation is its reduced Volatile Organic Compound (VOC) content. Traditional surface preparation often relies on solvents like acetone or Methyl Ethyl Ketone (MEK), which, while effective, pose significant health risks to operators and flammability hazards in the shop environment. Walter Surface Technologies has developed Surfox Pre-Weld to serve as a direct, safer functional alternative to these harsh solvents. It provides the rapid evaporation rate professionals require to maintain workflow speed, yet it does so without the overwhelming fumes associated with conventional thinners.

This 5-liter format is designed for high-volume fabrication environments. The liquid is ready-to-use straight from the container, eliminating the variables associated with dilution. It is particularly effective on stainless steel and aluminum, materials that are notoriously sensitive to surface impurities. By integrating Surfox Pre-Weld into the pre-welding protocol, fabricators can significantly reduce the rate of rework caused by surface contamination. The solution leaves behind no residue, ensuring that the chemical composition of the weld pool remains uncompromised. For industrial MRO operations seeking to upgrade their safety standards without sacrificing cleaning power, this product represents a superior choice in chemical surface treatment.

| Additional Information |

|---|

| packaging-description:1 per each |

| ----- new values below ---- |

| Volume:5 Liters |

| Container Type:Jug |

| Application:Pre-weld surface preparation, Degreasing |

| VOC Content:Reduced |

| Scent:Mild |

| brand:walter |

| format:liquid |

| packaging-description:1-per-each |