The Walter Defoamer Additive (53G002) is a specialized chemical solution engineered to tackle one of the most persistent challenges in industrial parts washing: excessive foam generation. In high-pressure or recirculating aqueous cleaning systems, agitation and contaminants can cause cleaning fluids to aerate, creating thick layers of foam. This foam not only obscures the operator's view of the parts being cleaned but can also lead to mechanical issues such as pump cavitation, where air bubbles interfere with fluid flow, reducing pressure and potentially damaging equipment. This 950ml bottle provides a potent, concentrated solution designed to break down foam bubbles instantly upon contact.

A critical feature of this additive is its silicone-free formulation. In many manufacturing environments, particularly those involving subsequent painting, coating, or plating, silicone contamination is a major liability. Silicone residues can cause "fish eyes" and adhesion failures in finishes. By using the Walter Defoamer, facilities can maintain rigorous quality control standards while ensuring their cleaning systems operate at peak efficiency. The product is specifically formulated to work synergistically with Walter's STAR and UNO families of aqueous cleaners and degreasers, ensuring that the chemical balance of the cleaning agent is not disturbed while the physical problem of foam is eliminated.

Economic efficiency is also a key benefit. Because the formula is highly concentrated, only a small amount is required to treat a large volume of cleaning solution. Operators can simply add the defoamer directly to the wash tank whenever foam levels begin to rise. It disperses quickly, providing immediate relief from overflow risks and restoring the full mechanical impact of the washer's spray jets. Whether you are cleaning machined parts, maintaining MRO equipment, or preparing surfaces for welding, this additive ensures your aqueous cleaning process remains clean, clear, and effective.

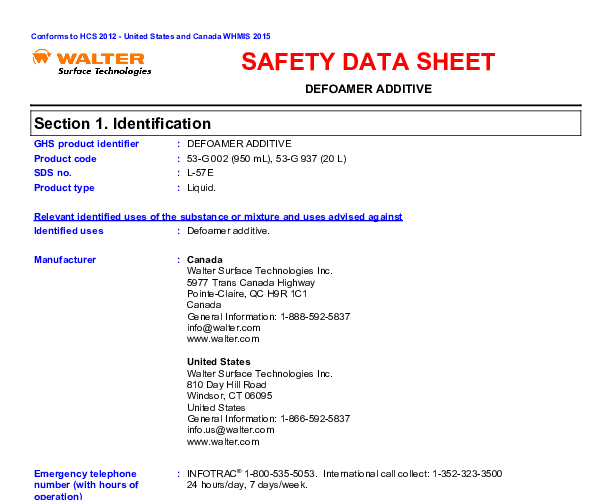

| Additional Information |

|---|

| packaging-description:1 per each |

| ----- new values below ---- |

| Container Size:950 ml |

| Silicone Free:Yes |

| Compatible Systems:STAR, UNO, Aqueous Parts Washers |

| Brand:Walter |

| Format:Liquid |

| Product:Defoamer |

| Packaging Description:950 ml Bottle |