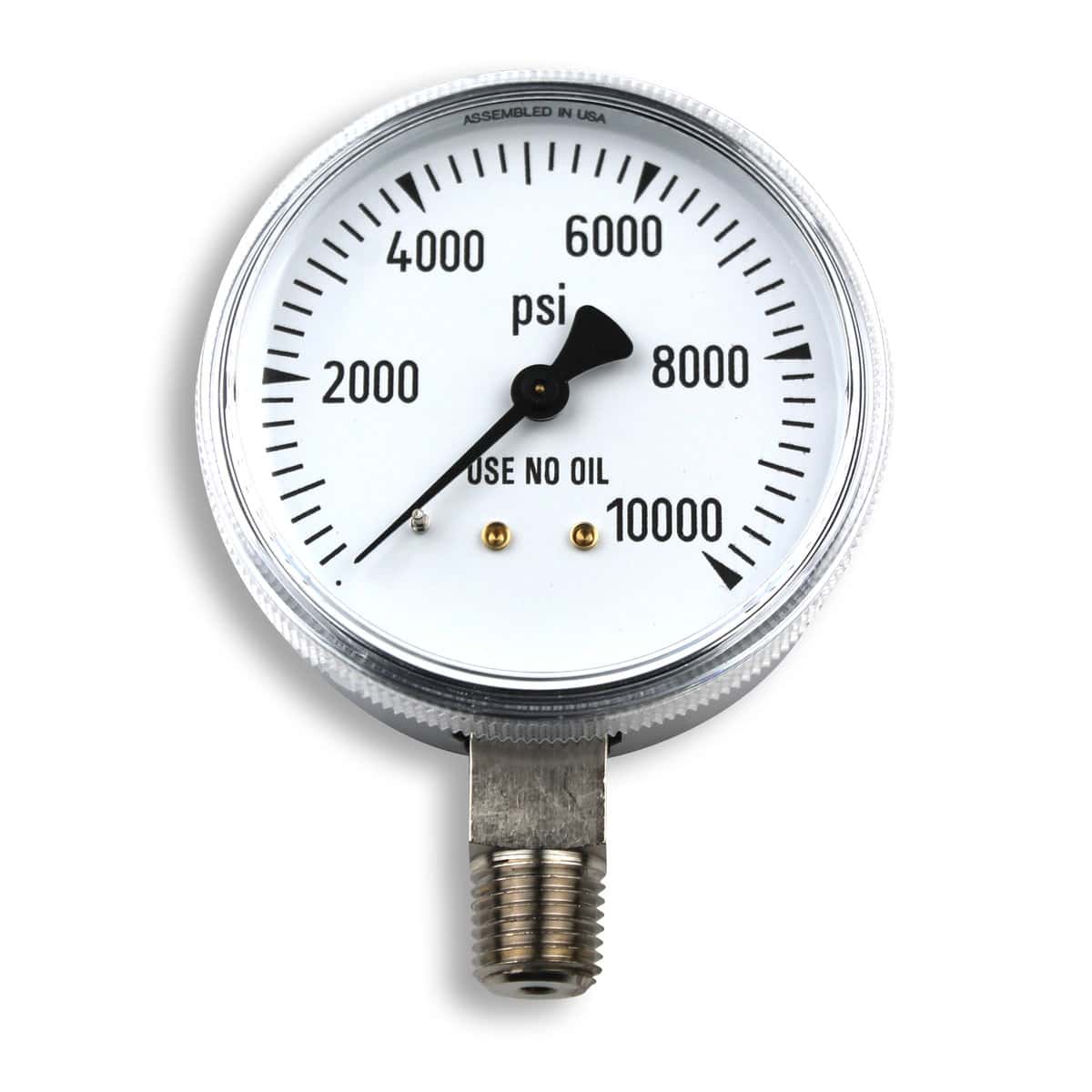

The Miller GA068-07 is a premium-grade pressure gauge designed to meet the rigorous demands of industrial maintenance and operation. Engineered with a robust Stainless Steel (SST) Chrome housing, this gauge is built to withstand harsh environments where corrosion, impact, and debris are common concerns. With a substantial pressure rating of 10,000 PSI, it serves as a critical component for monitoring high-pressure systems, ensuring that equipment operates within safe and optimal parameters. The 2.5-inch dial face provides a clear, legible display, allowing operators to quickly verify pressure levels from a distance, which is essential for maintaining workflow efficiency and safety protocols in busy industrial settings.

In the realm of MRO (Maintenance, Repair, and Operations), reliability is paramount. The Miller GA068-07 is manufactured to strict tolerances, ensuring consistent accuracy over its service life. This specific model is often utilized in specialized high-pressure manifolds, hydraulic systems, or heavy-duty welding gas distribution setups where standard gauges would fail. The chrome finish not only adds to the aesthetic appeal but primarily serves as a protective barrier against oxidation and chemical exposure. By integrating this genuine Miller component into your equipment, you ensure compatibility and performance that aligns with original equipment manufacturer (OEM) specifications.

Facility managers and procurement specialists will appreciate the longevity offered by the SST construction. Unlike plastic or lower-grade metal gauges that may crack or tarnish over time, the GA068-07 maintains its structural integrity. Whether used for troubleshooting pressure drops, verifying system capacity, or simply replacing a damaged unit on a fleet of machines, this gauge represents a solid investment in equipment uptime. Its standard 2.5-inch footprint makes it a versatile replacement option for various compatible assemblies requiring high-pressure monitoring capabilities.

Proper instrumentation is the backbone of safe industrial operations. A failing or inaccurate gauge can lead to system over-pressurization, equipment damage, or safety hazards. The Miller GA068-07 mitigates these risks by providing trustworthy readings up to 10,000 PSI. It is an essential stock item for maintenance departments managing high-pressure welding or hydraulic equipment, ensuring that when a gauge needs replacement, the downtime is minimal and the replacement part meets the highest standards of quality and durability.

| Additional Information |

|---|

| Packaging Description:1 Per Ea, 1 per each |

| Diameter (in):2.5" |

| Max Psi:10000 PSI |

| Used on a:Manifold, Regulator |

| Which Side?:Contents |

| Case Material:Chrome, Stainless Steel |

| Scale Type:Single Scale |

| Application:High Pressure Monitoring |

| ----- new values below ---- |

| Case Material:Stainless Steel, Chrome |

| Scale Type:Single Scale |

| Application:High Pressure Monitoring |

| Diameter (in):2.5" |

| Max Psi:10000 PSI |

| Packaging Description:1 per each |

| Used on a:Regulator, Manifold |

| Which Side?:Contents |