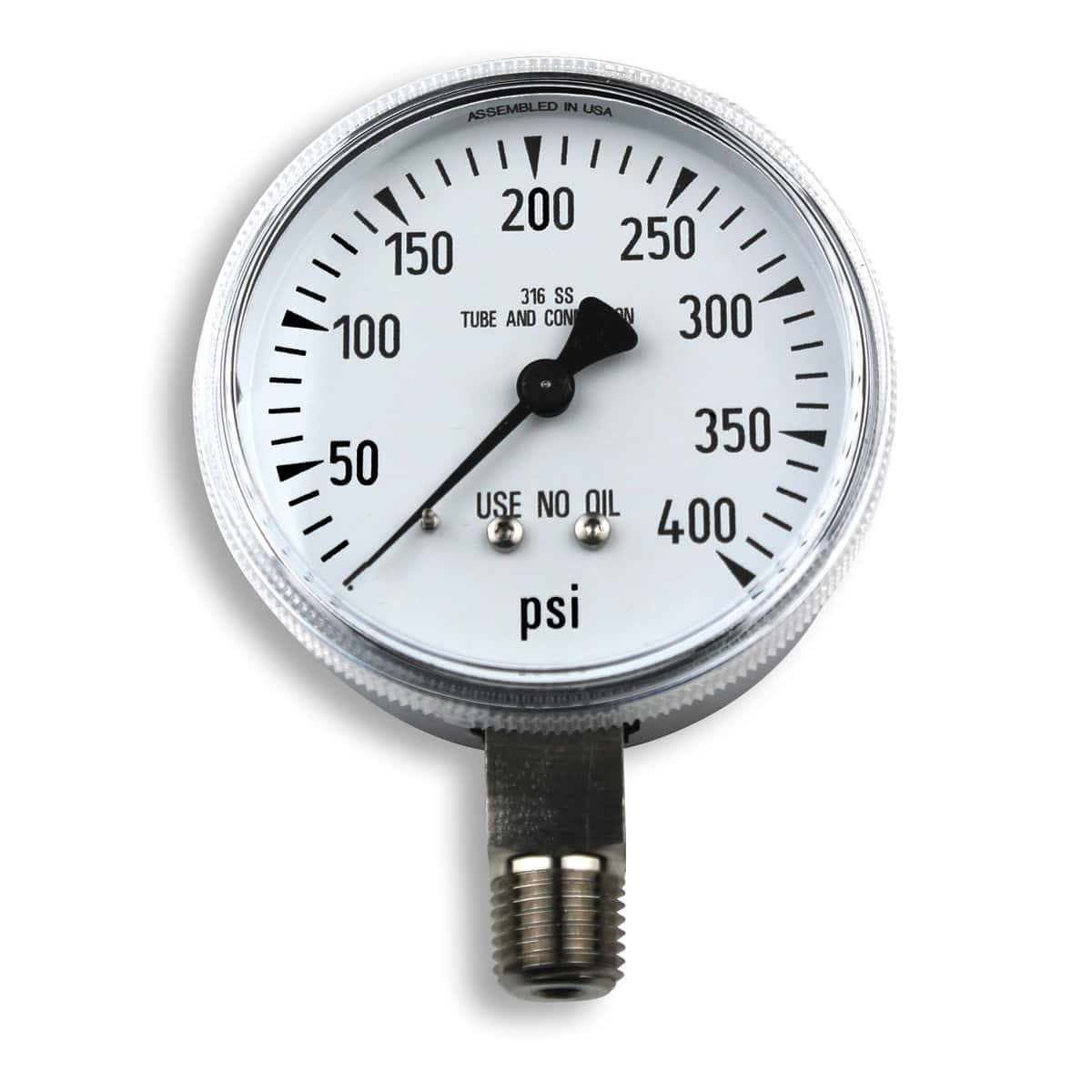

The Miller GA099-07 Gauge is a high-quality replacement component designed to restore the functionality and safety of your gas regulation equipment. In the realm of industrial welding and gas distribution, the accuracy of your delivery pressure is paramount. This gauge features a calibrated scale ranging from 0 to 400 PSI, making it specifically suited for the "using" or delivery side of heavy-duty regulators where higher working pressures are required, or for specific inert gas applications. Unlike standard low-pressure gauges that may top out at 100 PSI, this unit provides the headroom necessary for high-flow applications while maintaining the resolution needed for fine adjustments.

Constructed with a Stainless Steel (SST) Chrome housing, the GA099-07 is engineered to resist the corrosive elements often found in industrial environments. The chrome finish not only adds a layer of protection against oxidation and chemical exposure but also provides a professional aesthetic that matches high-end Miller regulators. The 2.5-inch diameter dial face is significantly larger than compact 1.5-inch or 2-inch gauges, offering superior visibility. This allows operators to monitor pressure fluctuations from a greater distance, enhancing safety protocols by reducing the need to be in immediate proximity to the equipment during operation.

Reliability in pressure measurement is critical for maintaining weld quality. A fluctuating or inaccurate gauge can lead to inconsistent gas shielding, resulting in porosity or poor bead profile. By installing a genuine Miller replacement gauge, you ensure that the internal mechanism—likely a robust Bourdon tube design—is calibrated to meet the stringent specifications of your Miller equipment. Whether used for MIG, TIG, or other gas-shielded processes, this gauge serves as a vital feedback loop for the operator, ensuring the set pressure matches the actual output delivered to the torch.

Installation of the GA099-07 is straightforward, typically utilizing a standard NPT connection (verify specific regulator thread size). It is an essential spare part for maintenance departments looking to minimize downtime caused by damaged or illegible gauges. By maintaining accurate pressure instrumentation, facilities can ensure compliance with safety standards and optimize gas consumption efficiency.

| Additional Information |

|---|

| Diameter (in):2.5" |

| Max Psi:400psi |

| Used on a:Regulator |

| Which Side?:Using |

| Case Material:Stainless Steel Chrome |

| Scale Type:Single Scale (PSI) |

| Mount Location:Bottom Mount |

| ----- new values below ---- |

| Case Material:Stainless Steel Chrome |

| Scale Type:Single Scale (PSI) |

| Mount Location:Bottom Mount |

| Diameter (in):2.5" |

| Max Psi:400psi |

| Used on a:Regulator |

| Which Side?:Using |