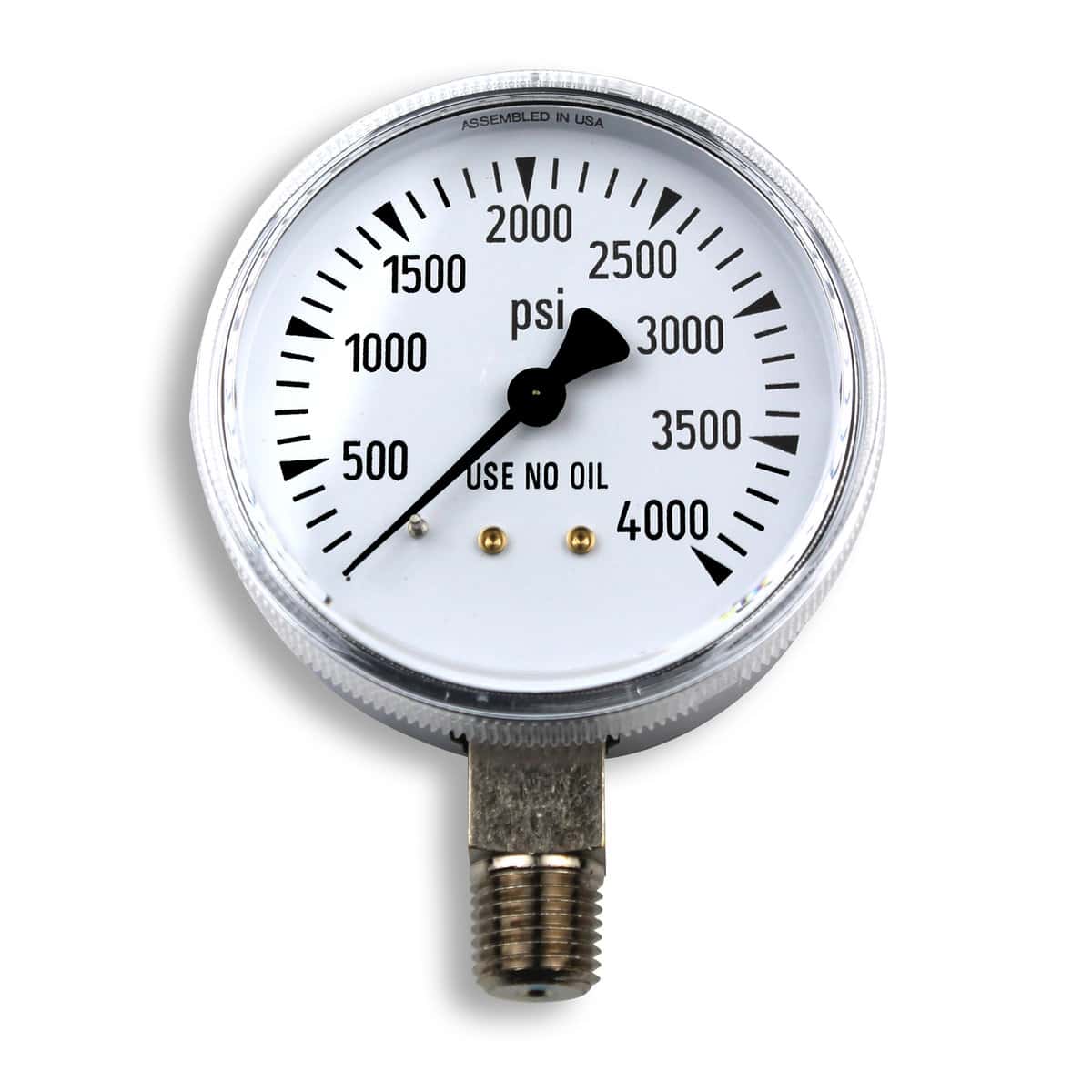

The Miller GA090-07 is a premium replacement pressure gauge designed for industrial gas regulation systems. Engineered to meet the rigorous demands of heavy-duty welding and fabrication environments, this gauge features a robust construction that ensures longevity and reliability. With a maximum pressure rating of 4000 PSI, it is specifically calibrated for monitoring the high-pressure side of regulators, typically indicating the remaining contents of gas cylinders such as Oxygen, Argon, or mixed shielding gases. Accurate pressure monitoring is critical for both process quality and facility safety, and this component delivers the precision required for professional operations.

Industrial environments expose equipment to physical impact, vibration, and corrosive elements. The GA090-07 addresses these challenges with a 2.5-inch dial encased in a stainless steel and chrome-finished housing. This finish not only provides a professional aesthetic that matches high-end Miller regulators but also offers significant resistance to oxidation and wear. The larger 2.5-inch face improves readability compared to standard 2-inch gauges, allowing operators to quickly verify gas levels from a distance, reducing downtime and enhancing workflow efficiency.

Safety in gas distribution systems relies on the integrity of every component. A compromised gauge with a stuck needle or cracked lens can lead to miscalculations in gas supply, potentially causing mid-weld runouts or safety hazards. This Miller genuine part is designed to integrate seamlessly with compatible Miller regulation equipment, ensuring a leak-free fit and reliable performance. The clear scale markings are easy to interpret, helping technicians maintain optimal cylinder management. Whether used for maintenance, repair, or operations (MRO) or as a stock spare for critical welding stations, the GA090-07 is an essential component for maintaining the operational readiness of your gas delivery infrastructure.

| Additional Information |

|---|

| Diameter (in):2.5" |

| Max Psi:4000psi |

| Used on a:Regulator |

| Used On Which Gas:Oxygen or Inert Gases |

| Which Side?:Contents |

| Material:Stainless Steel / Chrome |

| Product Type:Replacement Pressure Gauge |

| Scale Type:PSI |

| ----- new values below ---- |

| Material:Stainless Steel / Chrome |

| Product Type:Replacement Pressure Gauge |

| Scale Type:PSI |

| Diameter (in):2.5" |

| Max Psi:4000psi |

| Used on a:Regulator |

| Used On Which Gas:Oxygen or Inert Gases |

| Which Side?:Contents |