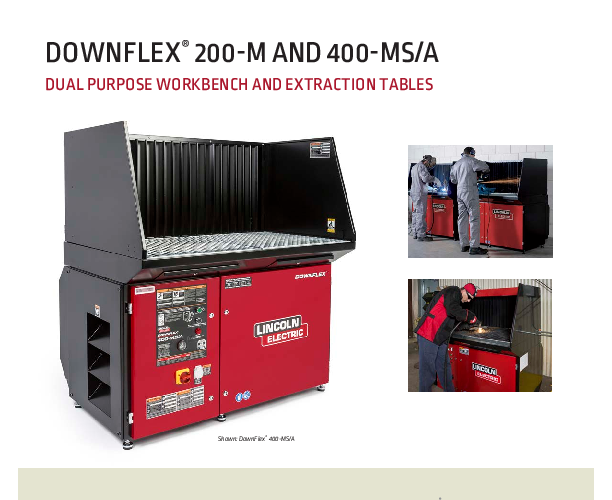

The Lincoln Electric DownFlex 200-M (K2751-13) is a dual-purpose downdraft table designed to function as both a robust workbench and a highly efficient fume extraction unit. Engineered for industrial environments, this model is specifically configured for facilities utilizing 460V or 575V 3-Phase power. The "M" designation indicates a Mechanical filter system, utilizing disposable filters that effectively capture particulate matter generated during welding, plasma cutting, and grinding operations. This system is an excellent choice for maintenance shops, trade schools, and fabrication facilities with light to medium duty cycles where automatic filter cleaning is not required.

One of the standout engineering features of the DownFlex 200-M is its dual-zone extraction capability. Air is drawn down through the perforated work surface (downdraft) and simultaneously through the rear panel (backdraft). This configuration ensures comprehensive fume capture, accommodating various workpiece sizes and welding positions. The system also incorporates a sophisticated 3-stage spark arrestor, which is critical for fire safety when the table is used for grinding applications. The spark arrestor prevents hot particulate from reaching the filter media, significantly reducing combustion risks.

Maintenance and monitoring are simplified with the integrated Magnehelic gauge located on the front control panel. This gauge provides real-time feedback on filter saturation, allowing operators to schedule filter replacements precisely when needed, maintaining optimal airflow performance. The unit's heavy-duty steel construction ensures it can withstand the rigors of daily industrial use, supporting heavy workpieces while providing a stable platform for precision work.

| Additional Information |

|---|

| Packaging Description:1 of each, 1 Per Ea |

| Item:Downdraft Table |

| Brand:Lincoln |

| Input Voltage:460V, 575V |

| Phase:3-Phase |

| Filter Type:Mechanical (Disposable) |

| Process Type:Flux Cored, Grinding, MIG, Plasma Cutting, Stick, TIG |

| ----- new values below ---- |

| Input Voltage:460V, 575V |

| Phase:3-Phase |

| Filter Type:Mechanical (Disposable) |

| Process Type:Stick, TIG, MIG, Flux-Cored, Plasma Cutting, Grinding |

| Extraction Method:Downdraft, Backdraft |

| Brand:Lincoln |

| Item:Downdraft Table |

| Packaging Description:1 of each |