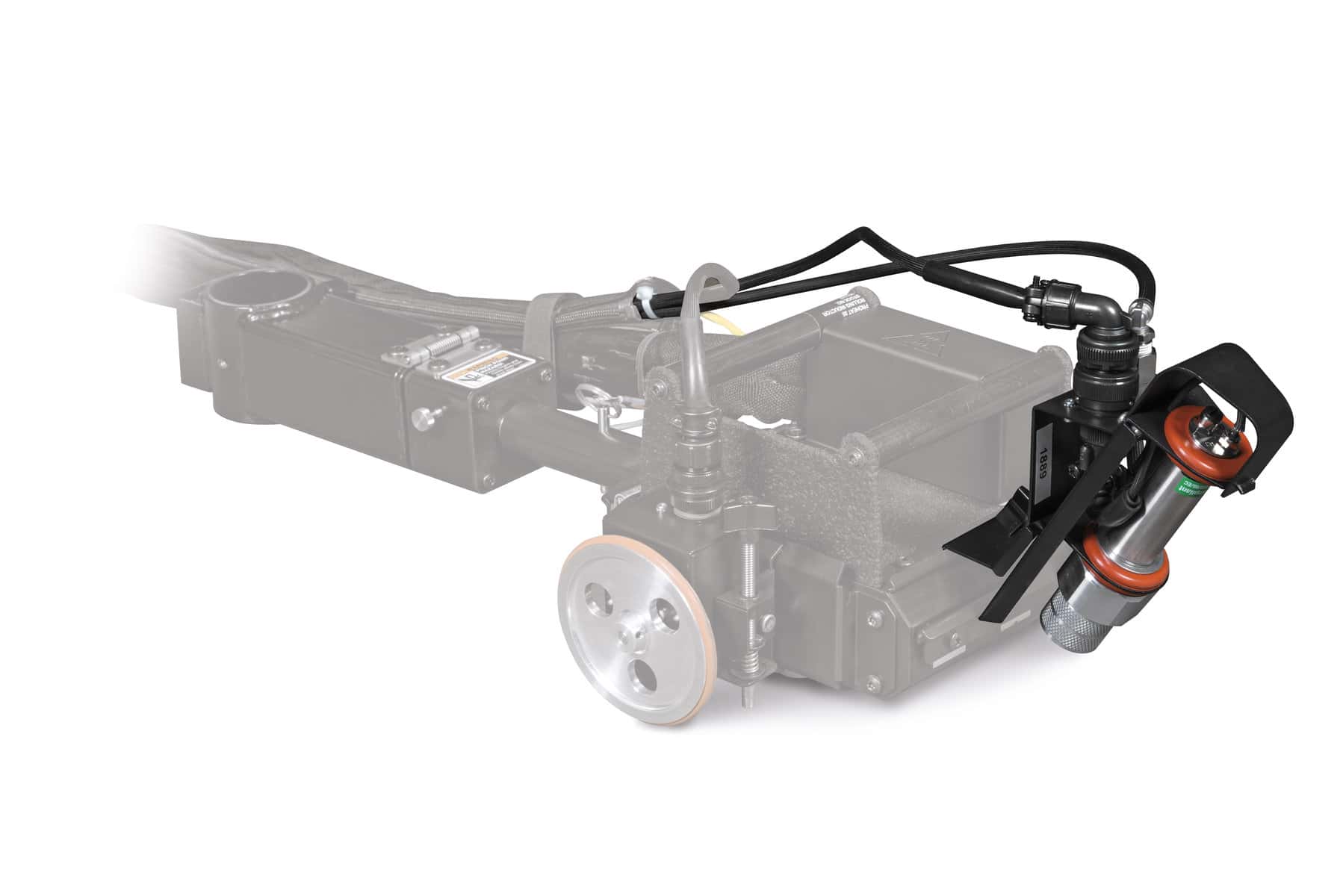

The Miller 301149 Infrared Temperature Sensor is a specialized accessory engineered for the ProHeat™ 35 Rolling Induction System. In industrial welding and fabrication environments, maintaining precise temperature control during preheating and stress relieving is critical for weld integrity and code compliance. Traditional contact sensors, such as thermocouples, often present challenges when dealing with moving workpieces, such as rotating pipes or rolling plates. The Miller 301149 solves this engineering challenge by utilizing advanced infrared technology to read the temperature of a moving part without physical contact.

This sensor offers a robust detection range of 122°F to 752°F (50°C to 400°C), covering the vast majority of preheat requirements for carbon steels and alloy materials. By integrating this sensor with the ProHeat 35 power source, operators can establish a closed-loop control system. The operator simply sets the desired target temperature on the interface, and the system utilizes the real-time feedback from the infrared sensor to modulate power output, heating the part to the specific temperature and holding it there with exceptional accuracy. This automation significantly reduces the margin for human error and ensures uniform heating across the heat zone.

Efficiency and safety are paramount in MRO and fabrication workflows. The use of the Miller 301149 eliminates the need for constant manual monitoring, freeing up operators to focus on other critical tasks while the system manages the thermal cycle. Furthermore, because the sensor works remotely, it removes the necessity for personnel to be in close proximity to the heated workpiece to take measurements, thereby reducing exposure to high temperatures and potential hazards. This unit is designed for easy setup and flexibility, accommodating a wide variety of pipe diameters and plate lengths, making it an indispensable tool for high-production shops utilizing Miller's induction heating technology.

Key Technical Benefits:

| Additional Information |

|---|

| Packaging Description:1 Per Ea |

| Temperature Range:122°F - 752°F, 50°C - 400°C |

| Sensor Type:Infrared |

| Compatible System:ProHeat 35 Rolling Induction System |

| Application:Moving Part Monitoring, Weld Preheating |

| Warranty:3 Months |

| ----- new values below ---- |

| Temperature Range:122°F - 752°F, 50°C - 400°C |

| Sensor Type:Infrared |

| Compatible System:ProHeat 35 Rolling Induction System |

| Application:Moving Part Monitoring, Weld Preheating |

| Warranty:3 Months |

| Brand:Miller OEM |

| Packaging Description:1 Per Ea |