Sorry, product has been discontinued by the vendor.

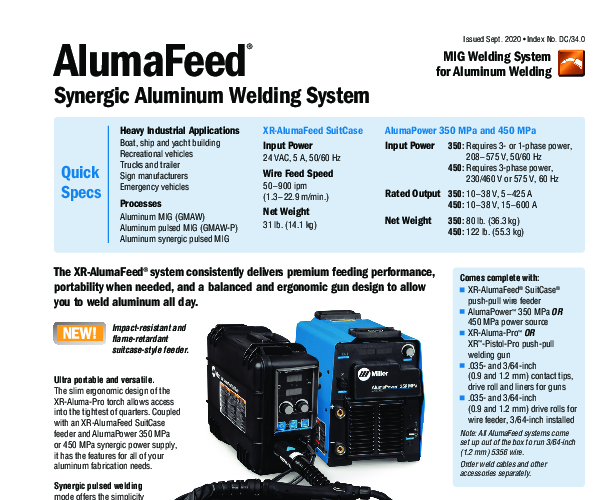

The Miller AlumaFeed 350 MIGRunner (951841) is a comprehensive welding system engineered specifically for high-performance aluminum fabrication. This package integrates the AlumaPower 350 MPa power source with the rugged XR-AlumaFeed Suitcase wire feeder and the ergonomic XR-Pistol Pro push-pull gun. Designed for industries such as shipbuilding, aerospace, and heavy manufacturing, this system addresses the unique challenges of welding aluminum, delivering consistent wire feeding and superior arc control.

At the core of this system is the AlumaPower 350 MPa, which features built-in Pulsed MIG programs tailored for the most common aluminum alloys, including 4000 and 5000 series. The Synergic Pulsed MIG mode simplifies operation by allowing the welder to adjust wire feed speed while the machine automatically optimizes voltage and amperage. Additionally, the Profile Pulse feature enables operators to achieve the coveted "stacked dime" bead appearance associated with TIG welding, but with the speed and deposition rates of MIG welding. This technology eliminates the need for complex gun manipulation, ensuring uniform weld aesthetics and quality.

The included XR-AlumaFeed Suitcase feeder is built to withstand harsh industrial environments. Its impact-resistant, flame-retardant case protects the wire from dirt and moisture, while the 30-foot XR-Pistol push-pull gun extends the welder's reach without compromising feed reliability. The system also utilizes Miller's Auto-Line Power Management technology, allowing for seamless connection to any input voltage between 208V and 575V, single or three-phase, making it an ideal solution for facilities with fluctuating or diverse power infrastructures.

This MIGRunner package comes fully equipped with a running gear cart, gas regulator, hoses, and cables, minimizing setup time. The inclusion of SharpArc technology allows for precise control over the arc cone and puddle fluidity, giving operators the ability to fine-tune the bead profile from flat and fluid to stiff and narrow. With Fan-On-Demand cooling, the unit operates quietly and efficiently, reducing the intake of airborne contaminants.

| Additional Information |

|---|

| Packaging Description:pack of 1 |

| Amps:350 |

| Weld Process:MIG (GMAW), Pulsed MIG (GMAW-P) |

| Input Voltage:208 V, 220 V, 230 V, 240 V, 460 V, 575 V |

| Amperage Range:5 A - 425 A |

| Cooling Method:Air Cooled |

| Portability:Portable Feeder, Wheeled Cart |

| ----- new values below ---- |

| Input Voltage:208 V, 220 V, 230 V, 240 V, 460 V, 575 V |

| Input Phase:1-Phase, 3-Phase |

| Amperage Range:5 A - 425 A |

| Output Voltage Range:10 V - 38 V |

| Wire Feed Speed:50 - 900 IPM |

| Cooling Method:Air Cooled |

| Portability:Wheeled Cart, Portable Feeder |

| Net Weight:50.35 kg |

| Dimensions:17.00 in (H) x 12.50 in (W) x 24.00 in (L) |

| Brand:Miller OEM |

| Amps:350 |

| Weld Process:MIG (GMAW), Pulsed MIG (GMAW-P) |

| Packaging Description:pack of 1 |