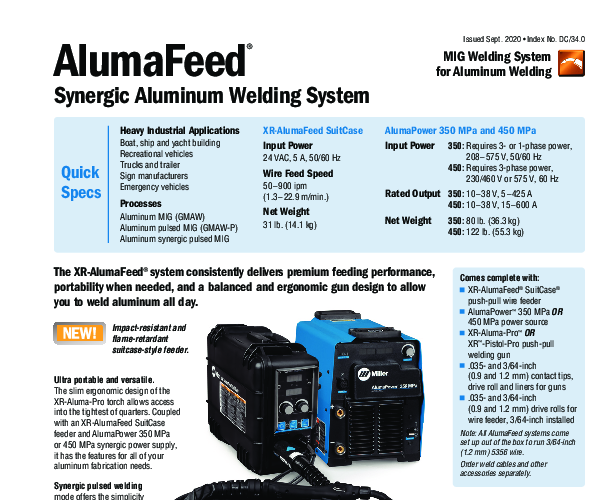

The Miller AlumaFeed 350 MPa MIGRunner with 25 ft. XR-Aluma-Pro Air-Cooled Gun (951833) is a dedicated aluminum welding package designed for the most rigorous industrial manufacturing environments. At the heart of this system is the AlumaPower 350 MPa power source, paired with the XR-AlumaFeed Suitcase wire feeder, delivering a synchronized push-pull feeding performance that resolves the traditional challenges of feeding soft aluminum wire. The system features Miller's Auto-Line Power Management technology, allowing for seamless connection to any input voltage from 208 to 575 V, single- or three-phase, without manual linking, ensuring operational flexibility across various job sites.

This package is engineered for high-deposition applications and superior weld quality. It utilizes Synergic Pulsed MIG technology, which simplifies operation by allowing the welder to adjust wire feed speed while the machine automatically optimizes voltage and pulse parameters. The proprietary Profile Pulse™ feature is a standout capability, modulating the output to create a "stacked dime" bead appearance typically associated with TIG welding, but with the travel speed and productivity of MIG. Additionally, SharpArc® controls allow technicians to fine-tune the arc cone and puddle fluidity, tailoring the bead profile to specific joint requirements.

Reliability is ensured through Wind Tunnel Technology™, which protects internal components from airborne contaminants, and Fan-On-Demand™, which operates the cooling system only when necessary to reduce noise and power consumption. The included XR-Aluma-Pro gun features a balanced, ergonomic design and industrial-grade cable relief, minimizing operator fatigue during extended shifts. With built-in programs for 4000 and 5000 series aluminum alloys and wire diameters up to 1/16 inch, the AlumaFeed 350 MPa is the definitive solution for heavy-duty aluminum fabrication in shipbuilding, truck manufacturing, and aerospace industries.

| Additional Information |

|---|

| Packaging Description:pack of 1 |

| Process Type:MIG (GMAW), Pulsed MIG (GMAW-P), Synergic Pulsed MIG |

| Input Voltage:208 V, 230 V, 460 V, 575 V |

| Phase:1-Phase, 3-Phase |

| Amperage Class:350 A |

| Duty Cycle:60% @ 350A |

| Cooling Type:Air Cooled |

| Application:Aluminum Welding |

| Wire Diameter Capacity:0.035 in, 3/64 in |

| Technology:Auto-Line, Profile Pulse, SharpArc |

| Warranty:3 Years (True Blue) |

| ----- new values below ---- |

| Included Gun:XR-Aluma-Pro 25 ft Air-Cooled |

| Wire Feeder Type:Push-Pull Suitcase |

| Wire Diameter Capacity:0.035 in, 3/64 in |

| Technology:Profile Pulse, Auto-Line, SharpArc |

| Warranty:3 Years True Blue |

| Brand:Miller Electric |

| Process Type:MIG (GMAW), Pulsed MIG (GMAW-P), Synergic Pulsed MIG |

| Input Voltage:208 V, 230 V, 460 V, 575 V |

| Phase:1-Phase, 3-Phase |

| Amperage Class:350 A |

| Duty Cycle:60% @ 350A |

| Cooling Type:Air Cooled |

| Gun Length:25 ft |

| Application:Aluminum Welding |