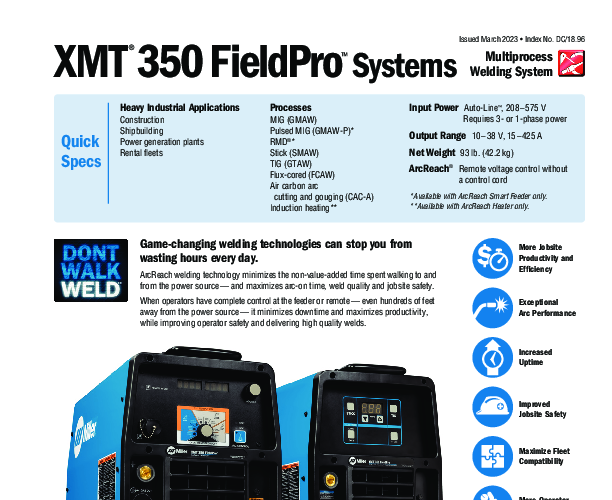

The Miller XMT 350 FieldPro Polarity Reversing Package (951735001) is a comprehensive industrial welding solution designed to address the specific challenges of field construction, shipbuilding, and heavy fabrication. This system integrates the robust XMT 350 FieldPro power source with the portable ArcReach SuitCase 12 wire feeder, creating a seamless workflow that maximizes arc-on time and minimizes setup complexity. At the core of this package is Miller's Quick-Select Polarity Reversing technology, which allows operators to switch between welding processes that require different polarities (such as switching from Stick to Flux-Cored) without manually disconnecting and reconnecting welding leads. This feature alone significantly reduces downtime associated with process changeovers.

The system utilizes ArcReach technology, a proprietary communication protocol that transmits control signals through the existing welding cables. This eliminates the need for fragile and expensive remote control cords, which are prone to damage in harsh job site environments. With the included ArcReach SuitCase 12, operators have full control over voltage and wire feed speed at the point of the weld, even when the power source is located hundreds of feet away. The power source features Auto-Line technology, enabling it to accept any input voltage from 208 to 575 VAC, single- or three-phase, without manual linking, ensuring compatibility with virtually any job site power grid.

Ideally suited for structural steel and pipe welding, the XMT 350 FieldPro delivers superior arc performance across all processes. It supports MIG (GMAW), Stick (SMAW), DC TIG (GTAW), Flux-Cored (FCAW), and Air Carbon Arc Cutting and Gouging (CAC-A). The machine is capable of gouging with carbons up to 5/16-inch diameter. Advanced features such as Cable Length Compensation (CLC) automatically adjust voltage to account for voltage drop in long weld cables, ensuring that the parameters set at the feeder are exactly what is delivered to the arc. The package includes the power source, the ArcReach SuitCase 12 feeder, and a rugged Bernard BTB 300 A MIG gun, providing a ready-to-weld solution for demanding industrial applications.

| Additional Information |

|---|

| Packaging Description:1 Per Ea, pack of 1 |

| Amps:350 |

| Voltage:208-575 V |

| Weld Process:Multi-Process |

| Process Type:Flux Cored, Gouging, MIG, Stick, TIG |

| Input Voltage:208-575 V |

| Output Range:10-425 A |

| Duty Cycle:60% @ 350A |

| Portability:Handle(s), Portable Feeder |

| Warranty:3 Years |

| ----- new values below ---- |

| Process Type:MIG, Stick, TIG, Flux Cored, Gouging |

| Input Voltage:208-575 V |

| Input Phase:1- and 3-Phase |

| Output Range:10-425 A |

| Duty Cycle:60% @ 350A |

| Net Weight:93 lb |

| Portability:Handle(s), Portable Feeder |

| Warranty:3 Years |

| Brand:Miller OEM |

| Amps:350 |

| Voltage:208-575 V |

| Weld Process:Multi-Process |

| Packaging Description:pack of 1 |