The Lincoln Electric SuperGlaze 5356 (ED700145) is a high-performance aluminum MIG welding wire designed to tackle the most demanding industrial applications. Engineered with Lincoln's proprietary SuperGlaze surface technology, this wire addresses the common challenges associated with feeding soft aluminum wire. The specialized surface treatment significantly reduces friction within the liner and contact tip, ensuring a smooth, consistent feed and virtually eliminating the frustration of "bird-nesting" or tangling at the drive rolls. This makes it an exceptional choice for automated systems and long conduit runs where feedability is critical.

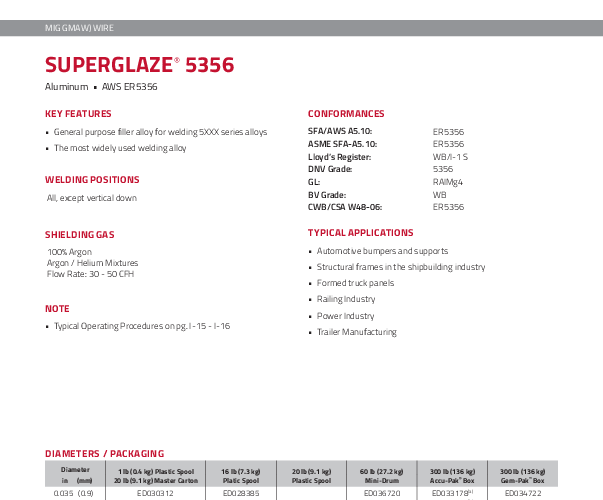

This 20 lb spool features a 0.035-inch (0.9 mm) diameter wire, classified as ER5356. As an aluminum-magnesium alloy (typically containing 5% magnesium), it offers distinct mechanical advantages over the softer 4043 alloys. It provides higher tensile strength and greater shear strength, making it the preferred filler metal for structural frames, shipbuilding, and heavy-duty trailer manufacturing. Additionally, the 5xxx series alloy delivers superior corrosion resistance, particularly in saltwater environments, which is essential for marine fabrication and repair.

Welders using the SuperGlaze 5356 will appreciate the stable arc and minimal spatter, which reduces post-weld cleanup time. The wire is also an excellent candidate for applications requiring anodizing after welding, as it provides a much closer color match to the base metal than 4xxx series wires, which often turn dark gray or black. Whether you are fabricating automotive bumpers, truck panels, or power industry components, this Lincoln Electric wire delivers the reliability and structural integrity required for professional results.

The stiffness of the 5356 alloy, combined with the SuperGlaze finish, allows for higher wire feed speeds and better push-feed performance compared to softer aluminum wires. It is compatible with standard DCEP (Direct Current Electrode Positive) MIG welding setups utilizing 100% Argon or Argon/Helium shielding gas mixtures.

| Additional Information |

|---|

| Packaging Description:20lb spool |

| Weld Process:MIG |

| AWS Spec :ER5356 |

| Diameter:0.035 |

| Packaging:20lb spool |

| Brand:Lincoln |

| Polarity:DC+ |

| Position:All Position |

| Material Composition:Aluminum Magnesium Alloy |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Wire Type:Solid |

| Tensile Strength:39,000 psi (Typical) |

| Spool Size:12 inch (300mm) |

| ----- new values below ---- |

| Material Composition:Aluminum Magnesium Alloy |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Wire Type:Solid |

| Tensile Strength:39,000 psi (Typical) |

| Spool Size:12 inch (300mm) |

| brand:lincoln |

| aws-spec:er5356 |

| diameter:0-035 |

| packaging:20lb-spool |

| weld-process:mig |

| polarity:dc |

| position:all-position |