The ESAB OK 61.30 is a high-performance, rutile-acid coated stick electrode classified as E308L-17 under AWS A5.4 standards. Engineered for precision and reliability, this 3.2mm electrode is specifically designed for welding austenitic stainless steels of the 19% Chromium, 10% Nickel type, such as AISI 304L and 308L. The 'L' designation indicates an extra-low carbon content (maximum 0.03%), which is critical for preventing carbide precipitation during the welding process. This feature significantly enhances the weld metal's resistance to intergranular corrosion, ensuring the longevity and structural integrity of the joint in demanding environments.

One of the defining characteristics of the OK 61.30 is its exceptional operator appeal. The rutile-based coating provides a soft, stable arc that operates smoothly on both AC and DC+ currents. This formulation promotes excellent wetting action, resulting in a flat to slightly concave bead profile with fine ripples. The slag system is designed to be self-releasing in many joint configurations, minimizing post-weld cleanup and grinding. This makes the electrode particularly suitable for applications where the aesthetic appearance of the weld is a priority, such as in architectural stainless steel or visible equipment surfaces.

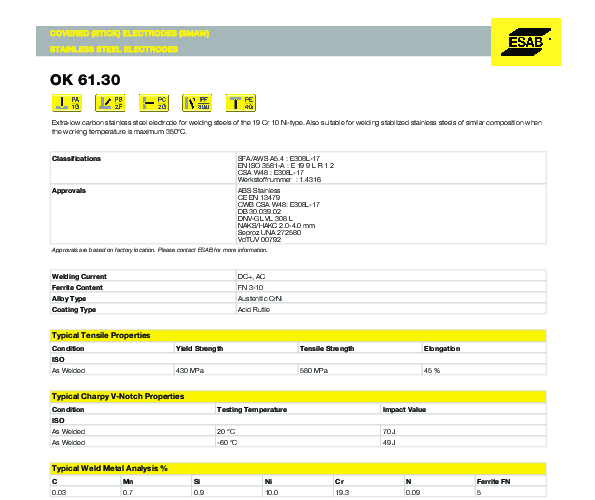

Technically, the deposited weld metal offers robust mechanical properties, including a typical yield strength of 430 MPa and a tensile strength of 560 MPa. The electrode provides a ferrite content in the range of FN 3-10, offering good resistance to hot cracking. It is also suitable for welding stabilized stainless steels of similar composition, provided the working temperature does not exceed 350°C. Whether utilized in the chemical, food processing, or general fabrication industries, the ESAB OK 61.30 delivers consistent, high-quality results that meet rigorous industrial standards.

| Additional Information |

|---|

| Packaging Description:4.1kg tube |

| Weld Process:Stick |

| AWS Spec :E308L-17 |

| Packaging:10lb tube |

| Grade:308 |

| Diameter:3.2mm |

| Polarity:AC or DC+ |

| Brand:Esab |

| Rod Type:Stick Electrode |

| Core Material:Stainless Steel |

| Coating Type:Rutile-Acid |

| AWS Classification:E308L-17 |

| Welding Position:All Position (Except Vertical Down) |

| Tensile Strength:560 MPa |

| ----- new values below ---- |

| Rod Type:Stick Electrode |

| Core Material:Stainless Steel |

| Coating Type:Rutile-Acid |

| AWS Classification:E308L-17 |

| Welding Position:All Position (except vertical down) |

| Tensile Strength:560 MPa |

| Ferrite Content:FN 3-10 |

| brand:esab |

| aws-spec:e308l-17 |

| diameter:3-2mm |

| grade:308 |

| weld-process:stick |

| polarity:ac-or-dc |