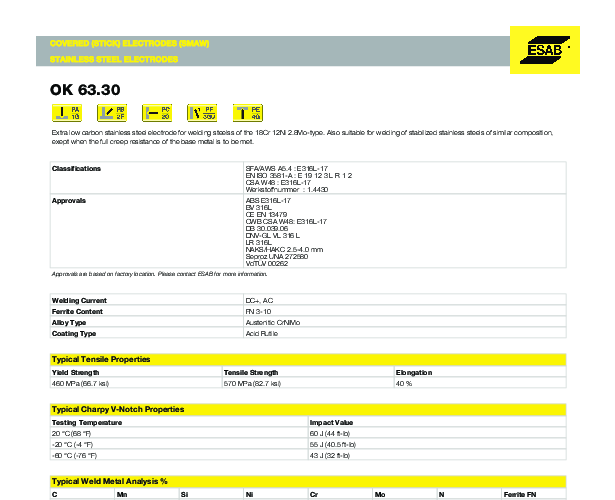

The ESAB OK 63.30 is a high-quality LMA (Low Moisture Absorption) stick electrode designed for the welding of extra low carbon 18Cr-12Ni-2.8Mo austenitic stainless steels. Classified as an AWS E316L-17, this consumable is engineered to provide superior resistance to corrosion, particularly against reducing acids and pitting environments. The 'L' designation indicates a maximum carbon content of 0.03% (typically 0.02% in this formulation), which is critical for preventing sensitization and intergranular corrosion in the heat-affected zone (HAZ) during service.

This electrode features a rutile-acid coating that delivers excellent arc stability and operability on both AC and DC+ currents. The chemical composition includes Molybdenum (Mo), which significantly enhances creep resistance at elevated temperatures and corrosion resistance in chloride-containing environments compared to standard 304/308 grades. It is also suitable for welding stabilized stainless steels of similar composition, such as AISI 316Ti, provided the working temperature does not exceed 400°C.

Industrially, the OK 63.30 is a staple in sectors requiring robust sanitary and chemical-resistant welds. It is widely utilized in the fabrication of chemical tankers, food processing equipment, textile machinery, and pharmaceutical piping systems. The electrode's metallurgy ensures that the weld metal matches the mechanical properties and corrosion resistance of the base material, meeting rigorous international standards including EN ISO 3581-A and CSA W48.

Technical specifications for the 3.2mm diameter variant typically recommend an amperage range of 70-110 A. The deposited weld metal exhibits a ferrite number (FN) in the range of 3-10, providing good resistance to hot cracking while maintaining excellent ductility and toughness. Storage and handling should follow standard low-hydrogen practices to maintain the coating's integrity and performance.

| Additional Information |

|---|

| Packaging Description:4.1kg tube |

| Weld Process:Stick |

| AWS Spec :E316L-17 |

| Packaging:10lb tube |

| Grade:316 |

| Diameter:3.2mm |

| Polarity:AC or DC+ |

| Brand:Esab |

| Rod Type:Stick Electrode |

| Coating Type:Rutile-Acid |

| Alloy Type:Austenitic Stainless Steel |

| Welding Position:All positions except vertical down |

| Current Type:AC, DC |

| ----- new values below ---- |

| Rod Type:Stick Electrode |

| Coating Type:Rutile-Acid |

| Alloy Type:Austenitic Stainless Steel |

| Welding Position:All Positions (except vertical down) |

| Current Type:AC, DC+ |

| Ferrite Content:FN 3-10 |

| Brand:Esab |

| Diameter:3.2mm |

| AWS Spec:E316L-17 |

| Grade:316 |

| Weld Process:Stick |

| Polarity:AC or DC+ |