The Harris ERCuAl-A2 Aluminum Bronze TIG Welding Rod is a premium copper-based alloy designed for high-stress joining and surfacing applications. Engineered to meet strict ANSI/AWS A5.7 and ASME SFA-5.7 standards, this filler metal is characterized by its intermediate strength and high ductility. The A2 classification indicates a specific composition of aluminum and iron within the copper matrix, which significantly enhances the mechanical properties of the weld deposit. With a tensile strength of 79,000 psi and a yield strength of 35,000 psi, this rod provides structural integrity comparable to many steels while retaining the unique benefits of bronze.

One of the primary technical advantages of this alloy is its exceptional resistance to corrosion, particularly in saline environments. This makes it an indispensable consumable for the fabrication and repair of marine hardware, desalination equipment, and chemical processing components. Beyond corrosion resistance, the deposit exhibits excellent wear characteristics, making it suitable for overlaying bearing surfaces, valve seats, and pump housings where metal-to-metal friction is a concern.

Metallurgically, the Harris ERCuAl-A2 is highly versatile. It is frequently specified for joining aluminum bronze base metals but is equally effective in dissimilar metal welding scenarios. It can reliably join steels and cast irons to copper, brass, and bronze alloys, providing a ductile interface that accommodates thermal expansion differences. The 1/16-inch diameter allows for precise heat control in TIG applications, ensuring sound welds with minimal dilution in sensitive overlay operations.

| Additional Information |

|---|

| Packaging Description:10 per tube |

| Weld Process:TIG |

| Grade:Aluminum, Aluminum Bronze |

| Packaging:10lb tube |

| Brand:Harris |

| Diameter:1.6mm |

| Position:n/a |

| Polarity:DC+, NA |

| AWS Classification:ERCuAl-A2 |

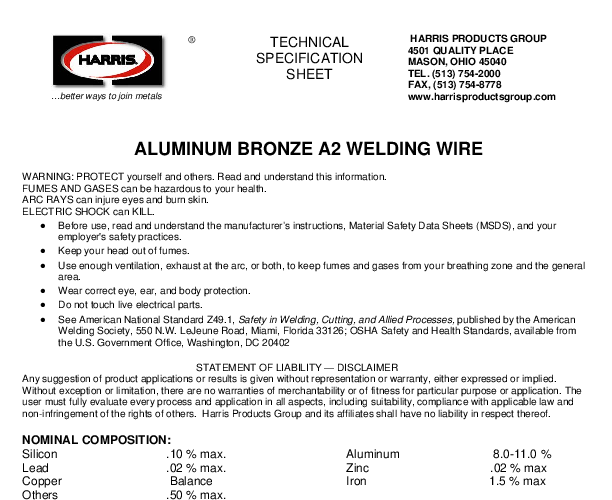

| Material Composition:Aluminum Bronze A2 |

| Tensile Strength:79,000 psi |

| Length :36" |

| ----- new values below ---- |

| AWS Classification:ERCuAl-A2 |

| Material Composition:Aluminum Bronze A2 |

| Tensile Strength:79,000 psi |

| Yield Strength:35,000 psi |

| Length:36" |

| Shielding Gas:100% Argon |

| brand:harris |

| diameter:1-6mm |

| weld-process:tig |

| packaging:10lb-tube |

| grade:Aluminum Bronze |

| polarity:dc |