The Josef 55.00 E7018-1M Steel Electrode (3/32" / 2.5mm) represents the pinnacle of our stick electrode manufacturing, designed specifically for welders who demand consistency, reliability, and superior mechanical properties. As part of the Josef 55.00 series, this electrode is engineered to exceed standard AWS requirements, offering the "1M" designation which certifies both improved impact toughness at lower temperatures and military-grade moisture resistance. This makes it the electrode of choice for critical structural projects where weld integrity cannot be compromised.

Our formulation utilizes a high-quality iron powder coating that serves multiple functions. Firstly, it increases the deposition rate, allowing for faster travel speeds and improved productivity on the job site. Secondly, it stabilizes the arc, providing a smooth, buttery feel that experienced welders appreciate. The arc stability is maintained even at lower amperages, which is crucial when welding in difficult positions or on thinner sections of heavy plate. The slag system is designed to be self-releasing in many instances, or easily detachable with a light chip, reducing post-weld cleanup time and the risk of slag inclusions in multi-pass welds.

Moisture pickup is the enemy of low-hydrogen electrodes, leading to hydrogen-induced cracking (cold cracking) in the heat-affected zone. The Josef 55.00 features an advanced coating formulation that resists moisture absorption from the atmosphere (H4R compliant), ensuring that the hydrogen content remains incredibly low even after the package has been opened for a shift. This is particularly vital for field work in humid environments or when welding high-strength low-alloy steels that are susceptible to cracking.

Packaged in a robust 12.30kg case, these electrodes are protected until you are ready to use them. Whether you are welding pressure vessels, offshore structures, or heavy earth-moving equipment, the Josef 55.00 E7018-1M delivers X-ray quality welds with excellent bead appearance and mechanical confidence. Trust in the Josef brand for consumables that drive industrial performance.

| Additional Information |

|---|

| Packaging Description:12.30kg per case |

| Weld Process:Electrode |

| Grade:Steel |

| Packaging:n/a |

| Brand:n/a |

| Diameter:2.5mm |

| Position:All Position, n/a |

| Polarity:DC+ / AC, NA |

| AWS Classification:E7018-1M |

| Rod Type:Stick Electrode |

| Coating Type:Low Hydrogen Iron Powder |

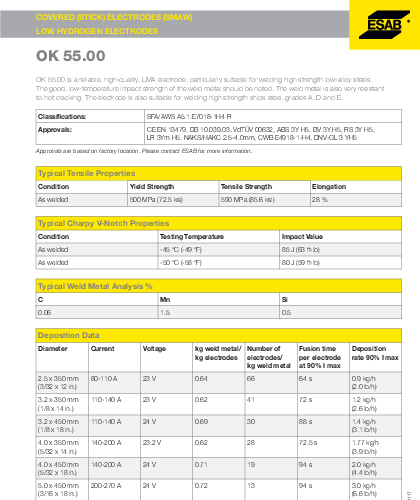

| Tensile Strength:70,000 psi (min) |

| Welding Current:AC, DCEP |

| ----- new values below ---- |

| Rod Type:Stick Electrode |

| Coating Type:Basic, Low Hydrogen |

| Length:14", 350mm |

| Tensile Strength:70,000 psi (min) |

| Impact Strength:High Low-Temp Toughness |

| Current Range:80-110 A |

| Brand:Esab |

| Diameter:2.5mm |

| AWS Spec:E7018-1 |

| Polarity:DC+ / AC |

| Position:ALL |