The ESAB OK 55.00 is a high-quality, low-hydrogen stick electrode (SMAW) engineered for the most demanding industrial applications. Classified as an AWS E7018-1, this electrode is renowned in the heavy fabrication industry for its exceptional mechanical properties and reliability. It is specifically designed to weld high-strength steels, making it a staple in sectors such as shipbuilding, offshore construction, and pressure vessel manufacturing. The 3.2mm (1/8") diameter is versatile enough for various joint configurations while providing the deposition rates necessary for efficient production.

One of the defining characteristics of the OK 55.00 is its superior resistance to hot cracking. This feature is critical when welding restrained joints or thick sections where thermal stresses are high. Furthermore, the electrode exhibits outstanding impact toughness at low temperatures, maintaining ductility down to -40°C. This makes it an ideal choice for projects in cold climates or applications subject to dynamic loading. The chemical composition is carefully balanced to ensure high metallurgical purity, resulting in X-ray quality welds that meet stringent inspection standards.

For professional welders, the operating characteristics of the OK 55.00 are equally impressive. It provides a stable, concentrated arc that is easy to control in all positions, including vertical-up and overhead. The slag system is designed for easy removal, often detaching in large pieces to reduce post-weld cleaning time. The bead profile is smooth and regular, minimizing the need for grinding. Whether you are welding Grade A, D, or E ship steel, or fabricating structural components for power generation, the ESAB OK 55.00 delivers the consistency and performance required for code-compliant work.

Storage and handling are simplified thanks to its moisture-resistant coating (LMA), which helps prevent hydrogen-induced cracking. However, for optimal results in critical applications, standard re-drying procedures for low-hydrogen electrodes should be followed. Trust ESAB's legacy of innovation and quality with the OK 55.00 for your next heavy-duty project.

| Additional Information |

|---|

| Packaging Description:18kg pack |

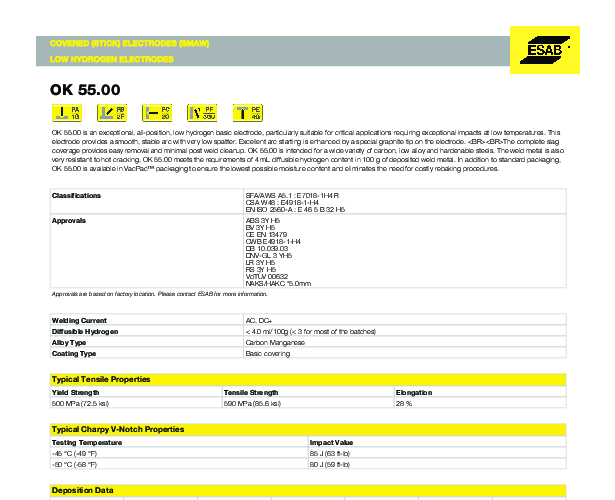

| AWS Spec :E7018-1 |

| Diameter:3.2mm |

| Brand:Esab |

| Polarity:AC/DC-, DC+ / AC |

| Position:ALL |

| Amp Range:100-160amp, 110-150amp |

| Rod Type:Stick Electrode (SMAW) |

| AWS Classification:E7018-1 H4 R |

| Coating Type:Basic Low Hydrogen |

| Tensile Strength:580 MPa |

| Current Type:AC, DC |

| ----- new values below ---- |

| Rod Type:Stick Electrode (SMAW) |

| AWS Classification:E7018-1 H4 R |

| Coating Type:Basic Low Hydrogen |

| Diameter / Length:3.2mm x 450mm (18") |

| Yield Strength:480 MPa |

| Tensile Strength:580 MPa |

| Impact Strength:115 J at -40°C |

| Current Type:AC, DC+ |

| Approvals:ABS, BV, DNV-GL, LR, CWB |

| Brand:Esab |

| Diameter:3.2mm |

| AWS Spec:E7018-1 |

| Amp Range:110-150amp |

| Polarity:DC+ / AC |

| Position:ALL |