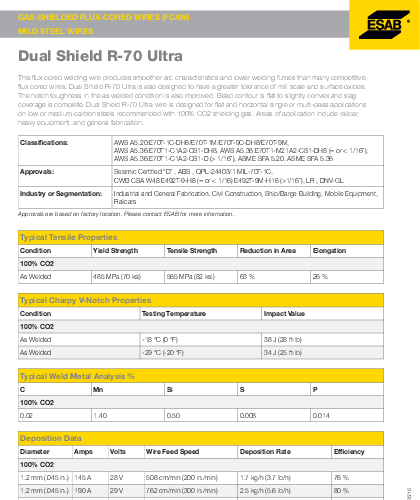

The Dual Shield R-70 Ultra is a premium gas-shielded flux-cored wire engineered for the rigorous demands of heavy industrial fabrication. Classified as E70T-1C-DH8, this wire is specifically formulated to provide superior weldability on low and medium carbon steels. Its 3/32-inch diameter and substantial 27.2kg coil packaging make it an optimal choice for automated or high-volume manual welding stations requiring extended run times and fewer changeovers.

One of the defining technical advantages of the R-70 Ultra is its robust tolerance for surface contaminants. In industrial environments where base materials often present mill scale, rust, or heavy oxides, this wire maintains arc stability and deposit integrity where other consumables might fail. It is designed to operate exclusively with 100% CO2 shielding gas, providing deep penetration and a cost-effective shielding solution without sacrificing mechanical properties. The resulting weld metal exhibits excellent notch toughness in the as-welded condition, meeting stringent structural requirements.

The slag system of the Dual Shield R-70 Ultra is formulated to provide complete coverage, protecting the cooling weld pool from atmospheric contamination. Upon cooling, the slag is easily detachable, revealing a bead profile that is flat to slightly convex—ideal for multi-pass heavy plate welding where tie-ins and stress distribution are critical. This wire is strictly designated for flat and horizontal positions, leveraging gravity to maximize deposition rates and travel speeds in applications such as railcar manufacturing, barge building, and civil construction.

By utilizing the Dual Shield R-70 Ultra, fabricators can expect a reduction in pre-weld cleaning time due to its oxide tolerance, and a reduction in post-weld cleanup due to its excellent slag release. It represents a high-efficiency solution for structural steel projects requiring consistent, high-quality welds with low diffusible hydrogen content.

| Additional Information |

|---|

| Packaging Description:27.2 kg per Coil |

| Weld Process:Flux Core |

| Diameter:2.5mm, 3/32" |

| Spool Size:27.2kg (60lb), 50lb coil |

| Brand:Esab |

| AWS Spec :E70T-1 |

| Position:Flat/Horizontal |

| Polarity:DC+, DCEP |

| AWS Classification:E70T-1C-DH8 |

| Shielding Gas Requirement:100% CO2 |

| Wire Type:Gas-Shielded Flux-Cored |

| Applications:Civil Construction, General Fabrication, Heavy Equipment, Railcar |

| ----- new values below ---- |

| AWS Classification:E70T-1C-DH8 |

| Shielding Gas Requirement:100% CO2 |

| Wire Type:Gas-Shielded Flux-Cored |

| Spool Size:27.2kg (60lb) |

| Polarity:DCEP |

| Applications:Railcar, Heavy Equipment, General Fabrication, Civil Construction |

| brand:Esab |

| diameter:3/32" |

| packaging-description:27.2 kg per Coil |

| weld-process:Flux Core |

| position:Flat/Horizontal |

| aws-spec:E70T-1 |