The Hobart Fabcor Ultimet 716 is a premium metal-cored welding wire designed to meet the rigorous demands of high-volume industrial manufacturing and heavy fabrication. Supplied in a substantial 500 lb drum, this .045-inch diameter wire is engineered for continuous, uninterrupted feeding, making it an exceptional choice for robotic cells and hard automation setups where downtime for spool changes must be minimized.

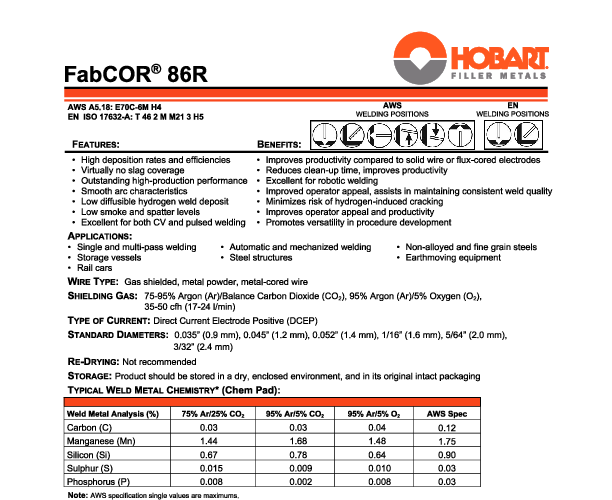

Meeting the AWS E70C-6M H4 classification, the Ultimet 716 delivers a powerful combination of high deposition rates and superior arc characteristics. Unlike traditional flux-cored wires, this metal-cored option produces significantly less fume and virtually no slag, leaving only small silicon islands that are easily removed. This reduces post-weld cleaning time and improves overall shop air quality. The "H4" designation guarantees very low diffusible hydrogen levels (less than 4ml per 100g of weld metal), providing excellent resistance to hydrogen-induced cracking in critical structural steel applications.

This wire is formulated to operate with Argon/CO2 shielding gas mixtures (typically 75-95% Argon), resulting in a smooth, stable arc with minimal spatter. It excels in single and multi-pass applications on mild and medium tensile steels. Whether used for heavy equipment manufacturing, railcar construction, or general structural fabrication, the Fabcor Ultimet 716 ensures consistent penetration, excellent bead profile, and the mechanical integrity required for high-stress environments.

| Additional Information |

|---|

| Packaging Description:500lb drum |

| Weld Process:Metal Core |

| Diameter:0.045 |

| Spool Size:500lb drum, 600lb drum |

| AWS Spec :E70C-6, E70C-6M |

| Polarity:DC+ |

| Wire Type:Metal-cored |

| AWS Classification:E491C-6M H4, E70C-6M H4 |

| Shielding Gas Requirement:75-95% Argon / Balance CO2 |

| Packaging Type:Drum |

| Current Type:DCEP |

| ----- new values below ---- |

| Wire Type:Metal-Cored |

| AWS Classification:E70C-6M H4, E491C-6M H4 |

| Shielding Gas Requirement:75-95% Argon / Balance CO2 |

| Packaging Type:Drum |

| Current Type:DCEP |

| Hydrogen Content:H4 (Less than 4ml/100g) |

| brand:hobart |

| diameter:0-045 |

| aws-spec:e70c-6m |

| weld-process:metal-core |

| packaging-description:500lb-drum |

| spool-size:500lb-drum |

| polarity:dc |