The Hobart FabCO Triple 7 is a premium gas-shielded flux-cored wire designed to meet the rigorous demands of heavy industrial fabrication. Engineered for versatility and performance, this 1/16-inch diameter wire is supplied in a 60lb coil, making it an economical choice for high-volume welding operations. It conforms to AWS A5.20 classifications E71T-1C H8 and E71T-1M H8, ensuring consistent mechanical properties and reliability in critical applications.

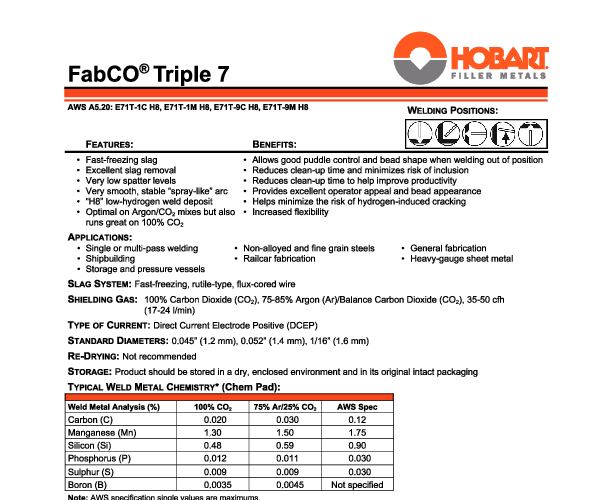

One of the defining characteristics of the FabCO Triple 7 is its fast-freezing slag system. This formulation allows for exceptional puddle control in all positions, particularly in vertical-up welding, where it supports high deposition rates without sacrificing bead shape. The wire is formulated to operate effectively with either 100% CO2 or a 75% Argon / 25% CO2 gas mixture, providing flexibility depending on the available shielding gas and desired arc characteristics. With a typical tensile strength of 88,000 psi (using CO2), it is well-suited for welding carbon steels and higher strength low-alloy steels.

Beyond its welding performance, the FabCO Triple 7 is designed with low hydrogen levels (H8 designation), minimizing the risk of hydrogen-induced cracking in thick sections or restrained joints. It also exhibits excellent impact toughness, with Charpy V-Notch values typically exceeding 40 ft-lbs at -20°F (-29°C), making it suitable for applications exposed to low service temperatures. The wire's chemistry is optimized to reduce fume generation, addressing modern safety concerns in enclosed or busy workshop environments.

This product is ideal for industries such as shipbuilding, railcar manufacturing, and heavy equipment repair, where weld integrity and productivity are paramount. The 60lb coil format reduces changeover downtime compared to smaller spools, further enhancing operational efficiency.

| Additional Information |

|---|

| Position:All Position |

| AWS Classification:E71T-1C H8, E71T-1M H8, E71T-9C H8, E71T-9M H8 |

| Shielding Gas Requirement:100% CO2, 75% Argon / 25% CO2 |

| Wire Type:Gas-Shielded Flux-Cored |

| Tensile Strength:88,000 psi (Typical with CO2) |

| Current Type:DCEP |

| ----- new values below ---- |

| AWS Classification:E71T-1C H8, E71T-1M H8, E71T-9C H8, E71T-9M H8 |

| Shielding Gas Requirement:100% CO2, 75% Argon / 25% CO2 |

| Wire Type:Gas-Shielded Flux-Cored |

| Tensile Strength:88,000 psi (Typical with CO2) |

| Yield Strength:76,000 psi (Typical with CO2) |

| Impact Strength:40 ft-lb at -20°F |

| Current Type:DCEP |

| Brand:Hobart |

| Diameter:1.6mm |

| Packaging Description:60lb coil |

| Weld Process:Flux Core |

| Position:All Position |

| Polarity:DC+ |