The ESAB Dual Shield 7100 Ultra is a premium gas-shielded flux-cored wire designed to meet the rigorous demands of heavy industrial fabrication. Engineered for versatility and efficiency, this 1/16" (1.6mm) diameter wire is supplied in a substantial 60 lb (27.2 kg) coil, making it an ideal choice for high-volume production environments where downtime for spool changes must be minimized. This product is formulated to operate across a broad range of welding parameters, providing fabricators with the flexibility needed to tackle diverse structural projects without constantly switching consumables.

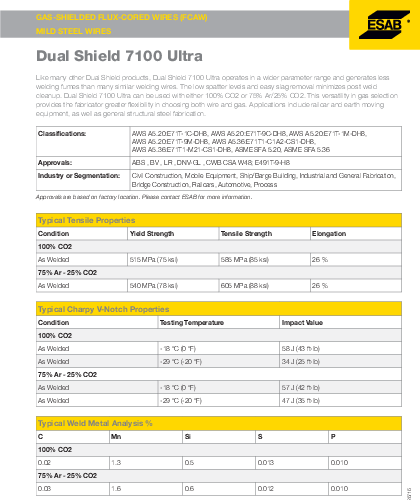

One of the standout characteristics of the Dual Shield 7100 Ultra is its dual gas compatibility. It performs exceptionally well with either 100% CO2, which offers deep penetration and cost savings, or a 75% Argon / 25% CO2 blend, which provides a smoother arc and reduced spatter. This adaptability allows procurement managers and shop foremen to utilize existing gas supplies or optimize their shielding gas choice based on specific project requirements. The wire is classified under AWS A5.20 as E71T-1CD and E71T-1, ensuring it meets strict industry standards for mechanical properties and weld quality.

In terms of operational safety and shop environment, the Dual Shield 7100 Ultra is engineered to produce lower welding fumes compared to many conventional E71T-1 wires. This feature is particularly beneficial in enclosed or semi-enclosed fabrication areas, contributing to better air quality and potentially reducing the load on fume extraction systems. The wire is suitable for all-position welding, making it a go-to solution for complex assemblies found in railcar manufacturing, earth-moving equipment production, and general structural steel fabrication. Its Seismic Certified "D" rating further attests to its reliability in critical infrastructure projects like bridge construction.

For industrial supply chains, stocking the ESAB Dual Shield 7100 Ultra ensures readiness for a wide array of carbon steel applications. Its combination of high deposition rates, excellent mechanical properties, and operator-friendly characteristics makes it a staple consumable for large-scale manufacturing and repair operations.

| Additional Information |

|---|

| Packaging Description:27.2kg spoo, 60lb coil |

| Weld Process:Flux Core |

| Diameter:1.6mm |

| Spool Size:60lb Coil |

| Brand:Esab |

| AWS Spec :E71T-1, E71T-1CD |

| Position:All Position |

| Polarity:DC+ |

| Trade Name:Dual Shield 7100 Ultra |

| Material Composition:Carbon Steel |

| Current Type:DCEP |

| ----- new values below ---- |

| Trade Name:Dual Shield 7100 Ultra |

| Shielding Gas:100% CO2, 75% Argon / 25% CO2 |

| Material Composition:Carbon Steel |

| Current Type:DCEP |

| Brand:Esab |

| Diameter:1.6mm |

| AWS Spec:E71T-1, E71T-1CD |

| Packaging Description:60lb coil |

| Position:All Position |

| Weld Process:Flux Core |