The Hobart FabCOR Edge is a premium metal-cored arc welding wire designed to meet the rigorous demands of modern fabrication environments. Classified under AWS A5.18 as E70C-6M-H4, this .045-inch diameter wire is engineered to deliver superior weld quality with a specific focus on surface chemistry and bead morphology. The "Edge" formulation distinguishes itself through a proprietary manufacturing process that manages the surface tension of the molten weld pool and the distribution of deoxidizers. This results in a significant reduction of silicon dioxide (silica) islands on the weld face and toe lines, a common issue with standard metal-cored and solid wires.

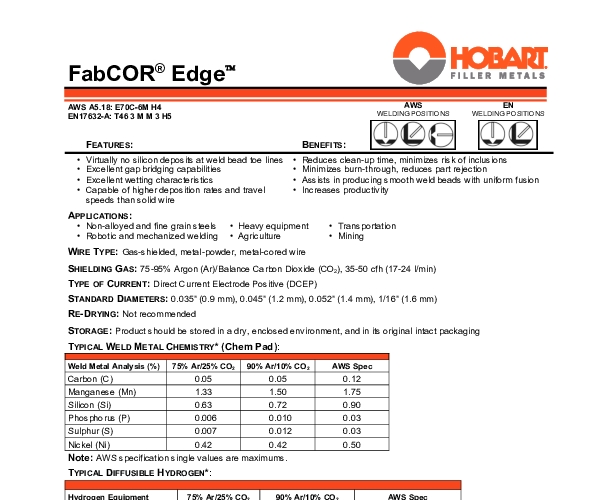

From a metallurgical perspective, the wire provides excellent mechanical properties consistent with the E70 series, offering a minimum tensile strength of 70 ksi. The "M" designation indicates its optimization for mixed shielding gases, specifically high-argon blends ranging from 75% to 95% Argon with a CO2 balance. This gas mixture promotes a stable, spray-transfer like arc that enhances deposition efficiency and penetration profiles. The H4 designation is critical for structural integrity, certifying that the wire produces less than 4ml of diffusible hydrogen per 100g of weld metal, thereby mitigating the risk of hydrogen-induced cracking (cold cracking) in susceptible steels.

The wire is formulated for single and multi-pass welding in flat and horizontal positions. Its fluid puddle characteristics allow for high travel speeds without compromising bead shape, making it an excellent choice for both semi-automatic and robotic applications. The reduction in spatter and the self-peeling nature of the thin slag (silicon islands) streamline the post-weld workflow, particularly in industries where immediate coating, painting, or plating follows the welding process. By minimizing the need for aggressive mechanical cleaning or chemical descaling, the FabCOR Edge improves overall throughput and operational efficiency.

| Additional Information |

|---|

| AWS Spec :E70C-6, E70C-6M |

| Position:All Position, Flat/Horizontal |

| AWS Classification:E70C-6M H4 |

| Wire Type:Metal-cored |

| Shielding Gas Requirement:75-95% Argon / Balance CO2 |

| Welding Position:Flat, Horizontal |

| Current Type:DCEP |

| ----- new values below ---- |

| AWS Classification:E70C-6M-H4 |

| Wire Type:Metal-Cored |

| Shielding Gas Requirement:75-95% Argon / Balance CO2 |

| Welding Position:Flat, Horizontal |

| Current Type:DCEP |

| Hydrogen Content:H4 (Less than 4ml/100g) |

| brand:Hobart |

| diameter:0.045 |

| packaging-description:33lb spool |

| spool-size:33lb spool |

| weld-process:Metal Core |

| aws-spec:E70C-6M |

| position:Flat/Horizontal |

| polarity:DC+ |